- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

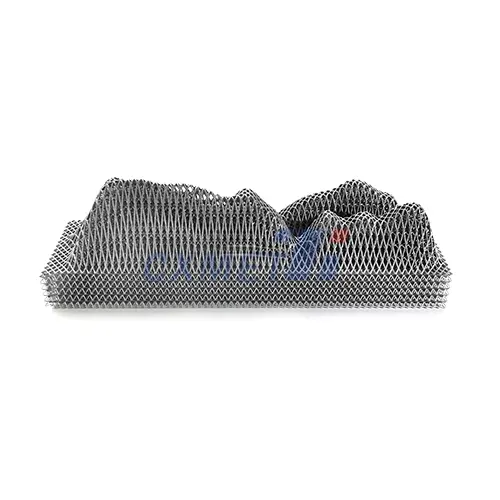

Electrolytic copper foil titanium anode

Place Of Origin:China

Material:Gr1 Titanium as substrate, platinum as coating

Dimension:Different dimension and shape are available, process according tocustomized design/ drawing

Packaging: standard export wooden cases or according to your requirements

Shipping: Support Air freight, Sea freight, Express freight

Welcome to Shaanxi CXMET Technology Co., Ltd., your trusted manufacturer and supplier of premium electrolytic copper foil titanium anodes. Our cutting-edge products are designed to meet the demanding needs of various industries, including electronics, battery production, and electroplating. With over 20 years of experience and a team of 80+ professional technicians, we offer superior quality, customization options, and excellent customer service.

Product Introduction

Our 【electrolytic copper foil titanium anodes】 are engineered for optimal performance in electrochemical processes. These anodes combine the exceptional conductivity of copper with the corrosion resistance of titanium, making them ideal for applications requiring high-precision and long-lasting components.

Key Features and Benefits

- Superior Conductivity: Ensures efficient current distribution

- Corrosion Resistance: Extends product lifespan in harsh environments

- Lightweight Design: Reduces overall system weight

- Uniform Coating: Provides consistent performance across the anode surface

- Customizable Dimensions: Tailored to fit your specific requirements

OEM and Customization Services: Customized Geometries and Exact Dimensions

At CXMET, we understand that one size doesn't fit all. Our team of experts can work with you to design and produce 【electrolytic copper foil titanium anodes】 that meet your exact specifications. Whether you need unique shapes, special coatings, or specific dimensions, we've got you covered.

Product Features

- High-purity copper foil (99.99% Cu)

- Titanium substrate for enhanced durability

- Precision-engineered surface for optimal performance

- Available in various thicknesses and sizes

- Resistant to chemical corrosion and mechanical wear

Technical Specifications

- Copper Purity: ≥99.99%

- Titanium Grade: ASTM Grade 1 or 2

- Copper Foil Thickness: 18-70 μm (customizable)

- Titanium Substrate Thickness: 1-3 mm (customizable)

- Standard Sizes: 500x1000mm, 600x1200mm (custom sizes available)

- Operating Temperature: Up to 80°C

- Current Density: Up to 50 A/dm²

Applications and Industries

Our 【electrolytic copper foil titanium anodes】 find applications in:

- Printed Circuit Board (PCB) Manufacturing

- Lithium-Ion Battery Production

- Electroplating and Surface Finishing

- Energy Storage Systems

- Electric Vehicle Battery Components

- Renewable Energy Technologies

- Advanced Electronics Manufacturing

|

|

|

|

|

|

Tips and Tricks

- Regular cleaning and maintenance can significantly extend anode lifespan

- Proper current distribution is crucial for optimal performance

- Consider using our anodes in conjunction with CXMET's other titanium products for a complete solution

Manufacturing Process

- High-purity copper foil production

- Titanium substrate preparation

- Precision bonding of copper foil to titanium

- Quality control inspections

- Custom shaping and sizing (if required)

- Final testing and packaging

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Us

High Quality: Only ASTM-certified raw materials

Advanced Equipment: Precision coating and welding machinery

Professional Team: 80+ skilled engineers and technicians

One-Stop Solution: From design to export logistics

Global Reach: Experience in 40+ export countries

Responsive Service: Fast quoting and technical support

OEM Services We provide full OEM/ODM support. Whether you require custom ribbon width, coating thickness, or special connectors, Shaanxi CXMET Technology Co., Ltd. can tailor the product to meet your exact application requirements.

FAQs

- Q: What is the typical lifespan of your electrolytic copper foil titanium anodes?

A: With proper maintenance, our anodes can last up to 5 years in standard operating conditions. - Q: Can you produce anodes for high-temperature applications?

A: Yes, we offer specialized versions designed for temperatures up to 120°C. - Q: What is the minimum order quantity?

A: We can accommodate orders as low as 10 pieces for standard sizes. - Q: Do you offer sample testing?

A: Absolutely! Contact us to arrange for sample anodes for your evaluation. - Q: How long does customization typically take?

A: Depending on specifications, custom orders usually take 2-4 weeks to complete.

Contact Us

Ready to elevate your manufacturing process with our high-performance electrolytic copper foil titanium anodes? Contact our expert team today for personalized support and solutions.

Email: sales@cxmet.com

Experience the CXMET difference – where quality meets innovation in titanium technology.

hotTags:Electrolytic copper foil titanium anode,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

_1768268508792.png)