- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

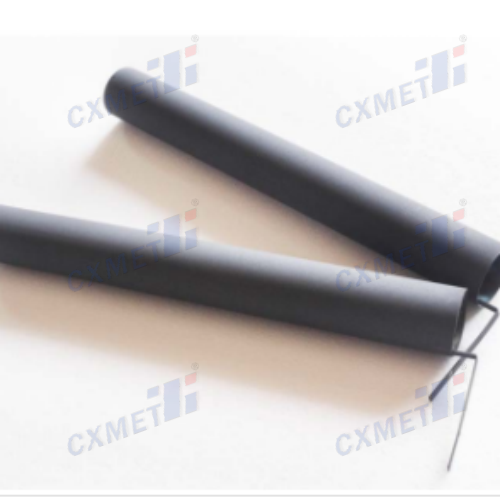

MMO Tubular titanium Anode

Place Of Origin:China

Material: GR1

Standard: ASTM B381

Material:Titanium Gr1

Size: Customizable.

Processing method: coating, brushing and sintering

Shipping: Support Air freight, Sea freight, Express freight

Chemical Composition: Titanium and mixed mental oxides

MMO Tubular Titanium Anodes: Advanced Solutions for Industrial Electrolysis

Shaanxi CXMET Technology Co., Ltd. is a leading manufacturer and supplier of MMO Tubular Titanium Anodes. With over 20 years of experience, we offer superior quality, customization options, and expert technical support. Our advanced manufacturing processes and stringent quality control ensure that our MMO Tubular Titanium Anodes meet the highest industry standards, providing reliable performance for various electrochemical applications.

Product Introduction

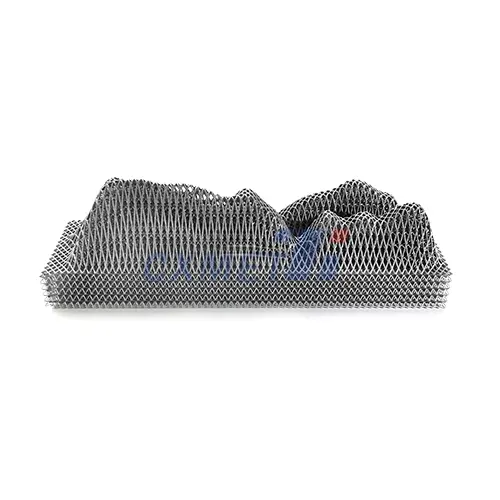

Our MMO Tubular Titanium Anodes are designed for optimal performance in demanding industrial environments. These anodes feature a titanium substrate coated with a mixed metal oxide (MMO) layer, combining durability with excellent electrochemical properties. The tubular design offers increased surface area and improved current distribution, making them ideal for large-scale electrolysis processes.

Key Features and Benefits

- High corrosion resistance in aggressive environments

- Extended lifespan compared to traditional anodes

- Low overpotential, reducing energy consumption

- Uniform current distribution for efficient electrolysis

- Customizable dimensions and coating compositions

- Excellent stability in chloride-rich solutions

- Suitable for both continuous and intermittent operations

OEM and Customization Services: Customized Geometries and Exact Dimensions

We understand that every industrial application has unique requirements. That's why we offer comprehensive OEM and customization services for our MMO Tubular Titanium Anodes. Our engineering team works closely with clients to design anodes that meet specific geometric needs and dimensional requirements. Whether you need special lengths, diameters, or connection types, we can tailor our anodes to fit your exact specifications.

Product Features

- Titanium substrate for exceptional durability

- Advanced MMO coating for optimal electrochemical performance

- Tubular design for increased surface area and improved current distribution

- Available in various diameters and lengths

- Multiple connection options (threaded, welded, or custom)

- Optimized for chlorine evolution and other electrochemical processes

Technical Specifications

- Substrate material: Grade 1 or 2 titanium

- Coating type: Mixed Metal Oxide (MMO)

- Standard diameters: 10mm to 100mm (custom sizes available)

- Standard lengths: Up to 3 meters (longer lengths on request)

- Operating current density: Up to 10 kA/m²

- pH range: 0-14

- Temperature range: Up to 80°C (higher temperatures available with special coatings)

Applications and Industries

Our MMO Tubular Titanium Anodes find extensive use in:

- Water and wastewater treatment

- Chlor-alkali production

- Metal recovery and electrowinning

- Cathodic protection systems

- Electroplating and surface finishing

- Chemical processing

- Pulp and paper bleaching

- Swimming pool disinfection

|

|

|

|

|

|

Tips and Tricks

- Regularly inspect anodes for signs of wear or coating degradation

- Maintain proper electrolyte circulation to prevent gas pocketing

- Ensure correct spacing between anodes and cathodes for optimal performance

- Monitor operating parameters to prevent overloading and premature failure

Manufacturing Process

Our MMO Tubular Titanium Anodes are produced using state-of-the-art manufacturing techniques:

- Titanium tube preparation and cleaning

- Application of proprietary MMO coating

- High-temperature sintering for coating adhesion

- Quality control inspections and testing

- Final assembly and packaging

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

How to Choose Products and Why Choose Products Made by Us

When selecting MMO Tubular Titanium Anodes, consider:

- Specific application requirements

- Electrolyte composition and operating conditions

- Required current density and expected lifespan

- Dimensional constraints of your system

Choose Shaanxi CXMET Technology Co., Ltd. for:

- Proven track record in electrochemical technologies

- Customization capabilities to meet unique needs

- Rigorous quality control and performance testing

- Comprehensive technical support and after-sales service

- Competitive pricing for high-quality products

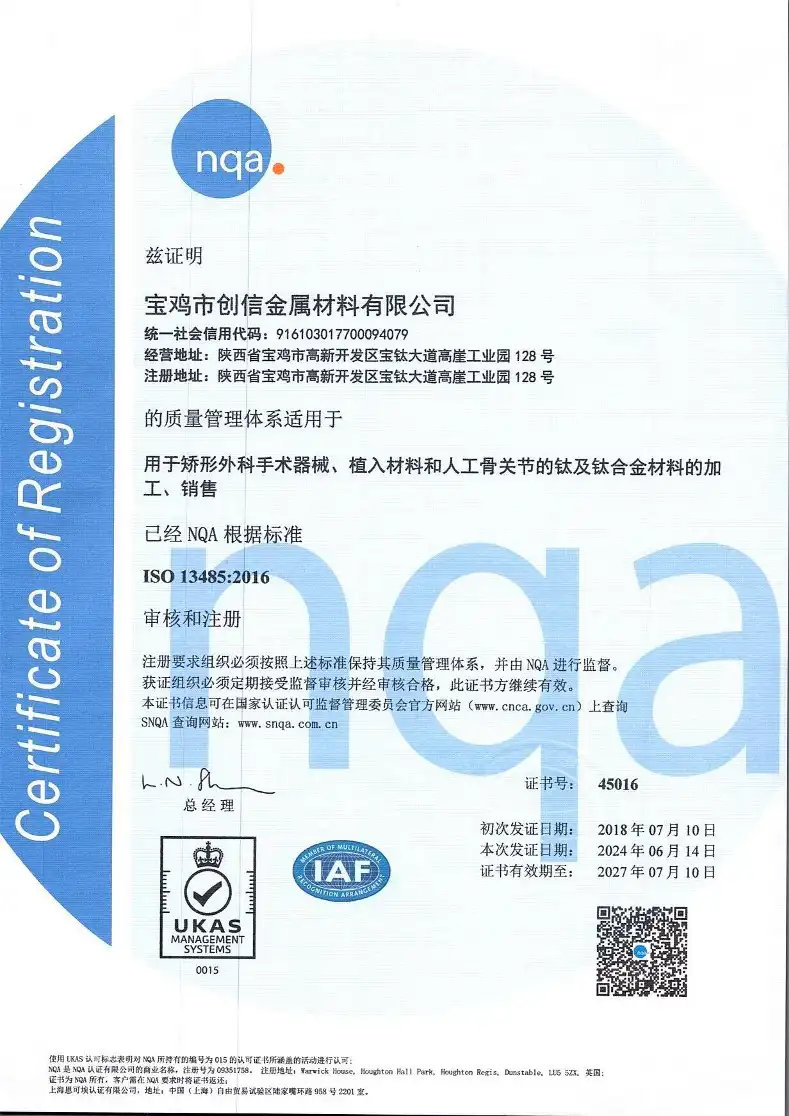

Certifications and Compliance

Our MMO Tubular Titanium Anodes meet or exceed industry standards:

- ISO 9001:2015 Quality Management System

- ISO 14001:2015 Environmental Management System

- ASTM B265 for titanium and titanium alloy strip, sheet, and plate

- NACE MR0175/ISO 15156 for use in H2S-containing environments

Quality Control and Testing

We maintain strict quality control measures throughout the production process:

- Raw material inspection and verification

- In-process quality checks at each manufacturing stage

- Dimensional and coating thickness measurements

- Electrochemical performance testing

- Accelerated life testing to ensure longevity

Packaging and Shipping

Our MMO Tubular Titanium Anodes are carefully packaged to prevent damage during transit:

- Individual protective wrapping for each anode

- Sturdy wooden crates or pallets for bulk orders

- Custom packaging solutions for oversized or specialty items

- Global shipping options with tracking and insurance

Testimonials and Case Studies

"Shaanxi CXMET's MMO Tubular Titanium Anodes have significantly improved our chlorine production efficiency. Their customization service allowed us to optimize our cell design, resulting in a 15% increase in output." - John D., Chief Engineer at a leading chlor-alkali plant

FAQs

- What is the typical lifespan of your MMO Tubular Titanium Anodes?

The lifespan varies depending on operating conditions but typically ranges from 5 to 10 years. - Can these anodes be used in seawater applications?

Yes, our anodes are well-suited for seawater electrolysis and cathodic protection in marine environments. - Do you offer rush order services for urgent projects?

We can accommodate rush orders on a case-by-case basis. Please contact our sales team for details.

Contact Us

Ready to upgrade your electrolysis system with our high-performance MMO Tubular Titanium Anodes? Contact our expert team today for personalized solutions and quotes.

Email: sales@cxmet.com

Tel&WhatsApp: 8615891192169

Trust Shaanxi CXMET Technology Co., Ltd. for your MMO Tubular Titanium Anode needs. Our commitment to quality, innovation, and customer satisfaction ensures that you receive the best products for your industrial electrochemical applications.

hotTags:MMO Tubular titanium Anode,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE