- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

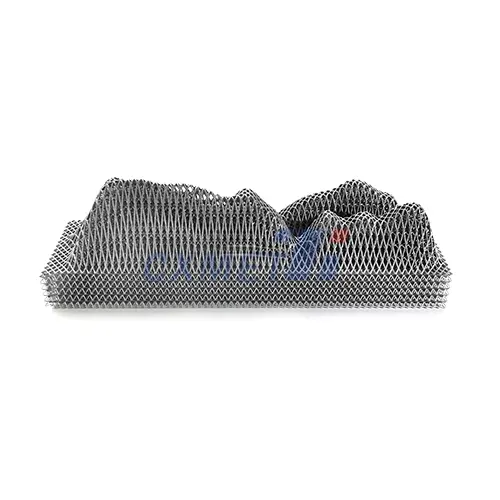

MMO Ribbon Anode

Place Of Origin: China

Material: Titanium, Mixed Metal Oxides Catalyst

Chemical Composition: Ti, RuO2, IrO2

Coating: Thickness 6~12 μm

Application: Environment Seawater

Color: Black

Life: >20yrs

Packing: Wooden Packing

Product Introduction

Shaanxi CXMET Technology Co., Ltd. offers high-performance MMO (Mixed Metal Oxide) ribbon anodes, designed for cathodic protection systems in aggressive environments. These anodes are manufactured using ASTM B265 Grade 1/2 titanium substrates and coated with a highly conductive and corrosion-resistant IrO2/Ta2O5 mixed metal oxide layer. Known for their exceptional stability, low wear rates (1-6 mg/A.a), and long service life under high current density, our MMO ribbon anodes are ideal for applications like tank bottom protection.

Product Features

Strong coating adhesion

Uniform coating thickness (>2μm)

Long lifespan even in chloride-rich conditions

Excellent electrical conductivity

Compatible with high current outputs

Simple installation and maintenance

Customizable according to service life and application environment

Product Usage

MMO ribbon anodes must be used with backfill materials to optimize their performance. Direct burial without backfill can cause rapid corrosion and reduced lifespan. Proper backfill, such as gypsum and sodium sulfate, enhances current efficiency and uniform corrosion of the anode surface. Ribbon anodes are often paired with magnesium or zinc sacrificial anodes to reduce grounding resistance. When installed along pipelines, connection intervals should not exceed 305 meters to prevent resistance build-up over time.

Product Parameters

| Chemical composition | ||||||||

| standard | iron% | carbon% | nitrogen% | hydrogen% | oxygen% | Impurities (single) % | Impurities (total) % | titanium% |

| ASTM B265Gr1 | <0.20 | <0.08 | <0.03 | <0.015 | <0.18 | <0.1 | <0.4 | margin |

| Electrochemical performance | ||||||||

| MMO with anode, rated current of 43mA/m, life span is more than 50 years. | ||||||||

| coating | ||||||||

| Coating crystal density 6-12 g/cm3; coating resistance 9-11 microohms/cm | ||||||||

| Coating thickness | ||||||||

| Coating thickness greater than 2.0 microns | ||||||||

Product Functions

Cathodic Protection: Prevents corrosion of buried or submerged metallic structures by acting as the primary current-discharging anode.

Uniform Current Distribution: Ensures even protection of the structure by minimizing potential gradients.

Chlorine/Oxygen Evolution: Depending on the environment, the anode enables Cl2 or O2 production to assist in surface reactions.

Stable Output Over Time: Maintains steady electrical output for long-term protection.

High Load Capacity: Supports large-scale infrastructure projects with high current demand.

Product Advantages

MMO ribbon anodes from Shaanxi CXMET Technology Co., Ltd. offer several compelling advantages. The use of ASTM-certified titanium substrates ensures mechanical robustness and corrosion resistance.

Manufacturing Process & Production Flow Our MMO ribbon anodes are manufactured through a precise multi-stage process:

Titanium Substrate Preparation: ASTM B265 Grade I/II titanium sheets are slit into standard-width ribbons and cleaned to remove oxides.

Surface Treatment: A series of chemical etching and rinsing steps improve adhesion by increasing surface roughness.

Coating Application: IrO2 and Ta2O5 precursors are applied via brush or dip coating, layer by layer, ensuring uniformity.

Thermal Treatment: Coated ribbons are sintered in a controlled atmosphere furnace at elevated temperatures to form the stable MMO layer.

Repeat Coating Cycles: Multiple cycles ensure desired thickness and catalytic activity.

Welding with Conductive Strips: Conductive titanium strips are welded crosswise using high-precision spot welders.

Final Inspection: Coating thickness, adhesion, and conductivity are tested to ASTM and customer standards.

Packaging: Finished products are carefully packed for safe global shipping.

Product Applications

Tank Bottom Cathodic Protection

Underground Pipelines

Marine Structures (e.g., piers, jetties)

Bridges in Saltwater Zones

Water Treatment Facilities

Tunnels and Underground Structures

Offshore Wind Power Foundations

Desalination Plants

Anode products in seawater typically evolve chlorine (Cl2), while in soils and fresh or brackish waters, oxygen (O2), chlorine, or both may be released depending on the electrolyte composition.

|

|

|

|

|

|

Packaging & Logistics Packaging:

Export-grade wooden crates for bulk shipments

Individual cardboard boxes for sample shipments

Protective foam inserts to prevent mechanical damage

Moisture-proof layers for marine environments

Customized packaging upon request

Complies with international export standards

Logistics:

Sea freight for large volumes

Air freight for urgent deliveries

Trucking for domestic transport

Multimodal logistics coordination

Express shipping (DHL, FedEx, UPS) for small lots

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Us

High Quality: Only ASTM-certified raw materials

Advanced Equipment: Precision coating and welding machinery

Professional Team: 80+ skilled engineers and technicians

One-Stop Solution: From design to export logistics

Global Reach: Experience in 40+ export countries

Responsive Service: Fast quoting and technical support

OEM Services We provide full OEM/ODM support. Whether you require custom ribbon width, coating thickness, or special connectors, Shaanxi CXMET Technology Co., Ltd. can tailor the product to meet your exact application requirements.

FAQ

What is the service life of MMO ribbon anodes?

Typically over 20 years under standard conditions with proper backfill.

Can the anode be customized for higher current outputs?

Yes, we offer custom configurations including thickness and coating composition.

Do you provide inspection certificates?

Yes, each shipment comes with full mill test reports and quality certificates.

What is the minimum order quantity?

Small batch samples are available; bulk pricing starts from 50 meters.

Can you deliver globally?

Yes, we have global export experience and can handle all logistics documentation.

Contact Us

Looking for a reliable supplier of MMO ribbon anodes for your cathodic protection projects? Contact Shaanxi CXMET Technology Co., Ltd. today for expert consultation, high-quality products, and competitive prices. We welcome global distributors, EPC contractors, and end-users to work with us.

Email: sales@cxmet.com

Tel&WhatsApp:8615891192169

hotTags:MMO Ribbon Anode,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE