- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

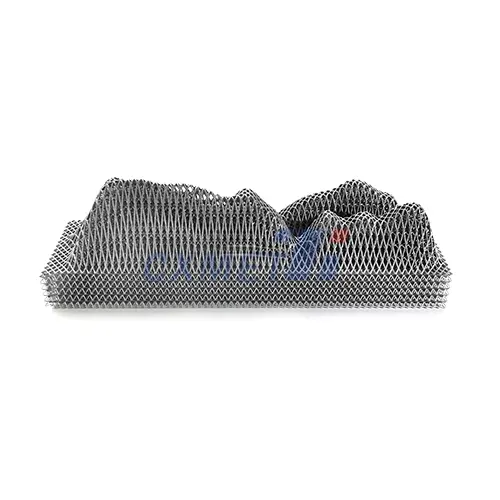

platinized titanium anode for cathodic protection

Place Of Origin:China

Material: GR1

Standard: ASTM B381

Material:Titanium Gr1

Size: Customizable.

Shape: plate, mesh, bar, etc.

Packaging: standard export wooden cases or according to your requirements

Processing method: coating, brushing and sintering

Shipping: Support Air freight, Sea freight, Express freight

Chemical Composition: Titanium and mixed mental oxides

ABOUT US

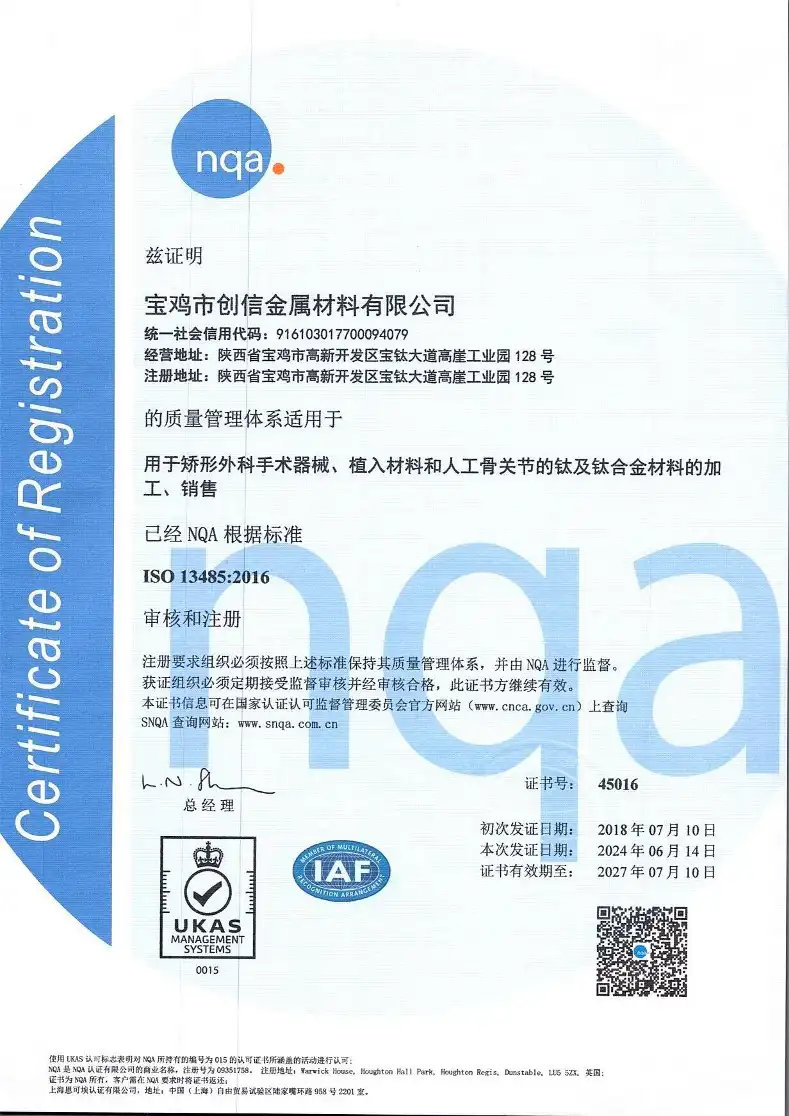

Shaanxi CXMET Technology Co., Ltd. is a leading manufacturer and supplier of high-quality platinized titanium anodes for cathodic protection. Our advanced anodes offer superior corrosion resistance, extended lifespan, and optimal performance for a wide range of industrial applications. With over 20 years of experience and a team of 80+ skilled technicians, we deliver innovative solutions tailored to your specific cathodic protection needs.

Product Introduction

Our platinized titanium anodes for cathodic protection are engineered to provide maximum protection against corrosion in harsh environments. These anodes feature a durable titanium substrate coated with a thin layer of platinum, combining the strength of titanium with platinum's excellent catalytic properties. The result is a highly effective, long-lasting solution for protecting critical infrastructure and equipment from corrosive damage.

Key Features and Benefits

- Superior Corrosion Resistance: Our anodes withstand aggressive environments, ensuring long-term protection.

- Extended Lifespan: Platinum coating significantly increases anode longevity, reducing replacement frequency.

- Low Consumption Rate: Minimal material loss during operation, ensuring consistent performance.

- High Conductivity: Excellent electrical properties for efficient cathodic protection.

- Versatile Application: Suitable for various industries and environments.

- Customizable: Tailored solutions to meet specific project requirements.

OEM and Customization Services: Customized Geometries and Exact Dimensions

At Shaanxi CXMET, we understand that every cathodic protection project has unique requirements. Our team of experts works closely with clients to design and manufacture platinized titanium anodes in custom shapes, sizes, and configurations. Whether you need mesh anodes, rod anodes, or specialized geometries, we can deliver precisely what your project demands.

Product Features

- Platinum coating thickness: 2.5 to 7.5 μm (customizable)

- Titanium substrate: Grade 1 or Grade 2 (ASTM B265)

- Low chlorine evolution potential

- High current density capacity

- Resistance to chemical attack

- Stable performance in various electrolytes

Technical Specifications

- Operating temperature: Up to 80°C (176°F)

- pH range: 0-14

- Current density: Up to 10,000 A/m²

- Design life: 20+ years (depending on operating conditions)

- Available shapes: Mesh, rod, ribbon, tube, and custom designs

Applications and Industries

Our platinized titanium anodes for cathodic protection are widely used in:

- Oil & Gas: Offshore platforms, pipelines, storage tanks

- Marine: Ship hulls, port facilities, offshore wind farms

- Water Treatment: Desalination plants, water distribution systems

- Chemical Processing: Storage tanks, process equipment

- Infrastructure: Bridges, dams, reinforced concrete structures

- Mining: Underground structures, processing equipment

|

|

|

|

|

|

Tips and Tricks

- Regular inspection and maintenance of your cathodic protection system can significantly extend its lifespan.

- Proper anode placement is crucial for optimal protection. Consult our experts for guidance on system design.

- Monitor and adjust your system's output to ensure consistent protection as environmental conditions change.

Manufacturing Process

Our platinized titanium anodes are produced using state-of-the-art equipment and rigorous quality control processes:

- Titanium substrate preparation and cleaning

- Application of platinum coating using advanced electroplating techniques

- Heat treatment for improved coating adhesion

- Quality inspection and testing

- Custom shaping and finishing as required

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Us

High Quality: Only ASTM-certified raw materials

Advanced Equipment: Precision coating and welding machinery

Professional Team: 80+ skilled engineers and technicians

One-Stop Solution: From design to export logistics

Global Reach: Experience in 40+ export countries

Responsive Service: Fast quoting and technical support

OEM Services We provide full OEM/ODM support. Whether you require custom ribbon width, coating thickness, or special connectors, Shaanxi CXMET Technology Co., Ltd. can tailor the product to meet your exact application requirements.

FAQs

- What is the typical lifespan of your platinized titanium anodes?

Our anodes can last 20+ years under proper operating conditions. - Can you provide anodes for high-temperature applications?

Yes, we offer specialized anodes for high-temperature environments up to 80°C. - Do you offer installation services?

While we don't provide direct installation, we offer technical guidance and can recommend certified installers.

Contact Us

Ready to protect your assets with our high-performance platinized titanium anodes for cathodic protection? Contact our team of experts today for a personalized consultation and quote.

Email: sales@cxmet.com

Trust Shaanxi CXMET Technology Co., Ltd. for innovative, reliable, and customized cathodic protection solutions that stand the test of time.

hotTags:platinized titanium anode for cathodic protection,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

_1768270522923.jpg)