- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

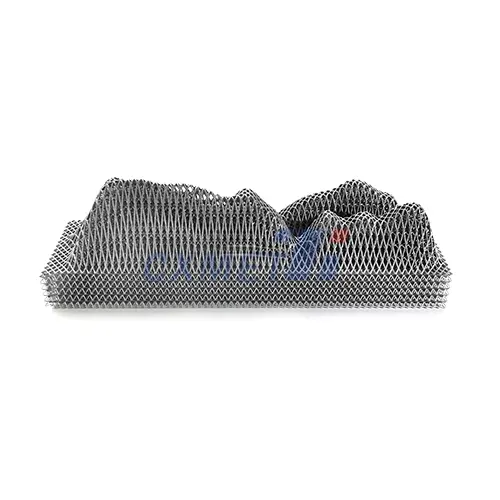

Titanium Welding Rod

Place Of Origin: China

Grade: Gr1 Gr2 Gr7 Gr5

Ti (Min): 99.6%

Strength: 345MPa

Surface: Pickling Polished

Shape: Spool Coil Straight

Standard: ASTM B863

Certification: ISO9001:2015

Strength: 435MPa

Application: Industrial

Introduction to Titanium Welding Rod

Shaanxi CXMET Technology Co., Ltd. proudly presents our premium Titanium Welding Rods, engineered for superior welding performance across diverse industries worldwide. As a leading manufacturer based in the heart of "China Titanium Valley," we specialize in advanced titanium materials and welding consumables designed to meet the stringent demands of aerospace, marine, chemical, medical, and energy sectors.

Our Titanium Welding Rods combine exceptional strength, corrosion resistance, and excellent weldability, ensuring reliable and durable joints even under extreme conditions. Manufactured with precision and quality control, our rods are the preferred choice for fabricators and engineers who require consistent performance and long-term durability.

Key Features of Titanium Welding Rods

-

High Strength-to-Weight Ratio: Titanium's low density combined with high tensile strength makes our welding rods ideal for applications requiring strong yet lightweight joints.

-

Superior Corrosion Resistance: Excellent resistance to seawater, acidic, and oxidizing environments protects welded structures from premature failure.

-

Wide Range of Titanium Grades: From commercially pure grades (Gr1, Gr2) to high-performance α+β alloys (Gr5, Gr23), we supply rods optimized for various mechanical and environmental conditions.

-

Excellent Weldability: Designed for TIG and plasma welding, our rods provide smooth arc stability and minimal contamination.

-

Biocompatibility: Our rods made from medical-grade titanium alloys (Gr23) meet the highest standards for surgical implants and biomedical devices.

-

Heat Resistance: Select grades such as Gr5 and Gr22 maintain strength and integrity under elevated temperatures, suitable for aerospace and power generation components.

-

Consistent Quality: Manufactured under stringent quality control with certified chemical composition and mechanical properties, ensuring repeatable results.

Specifications of Titanium Welding Rods

| Grade | Type | Alloy Composition | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Typical Applications |

|---|---|---|---|---|---|---|

| Gr1 | Commercial Pure Titanium | ≥99.5% Ti | 240 | 170 | 24 | Medical, Chemical, Marine |

| Gr2 | Commercial Pure Titanium | ≥99.2% Ti | 345 | 275 | 20 | Heat Exchangers, Pipelines |

| Gr5 | α+β Alloy | Ti-6Al-4V | 895 | 828 | 10 | Aerospace, Racing, Military |

| Gr7 | Pure Titanium + Pd | Ti + 0.2% Pd | 340 | 275 | 20 | Chloride Environments, Chemical |

| Gr9 | α Alloy | Ti-3Al-2.5V | 620 | 483 | 15 | Bicycle Frames, Aircraft Tubing |

| Gr23 | α+β Alloy (ELI) | Ti-6Al-4V ELI | 860 | 795 | 14 | Medical Implants, Dental |

| Gr22 | α+β Alloy | Ti-5Al-2.5Sn | 760 | 690 | 13 | Aerospace Jet Engines |

Our Titanium Welding Rods come in various diameters ranging typically from 1.6 mm to 6 mm and lengths customizable according to customer requirements.

|

|

Applications of Titanium Welding Rods

Titanium Welding Rods from Shaanxi CXMET are widely applied in:

-

Aerospace Industry: Welding critical components such as aircraft frames, engine parts, and landing gear.

-

Marine Engineering: Fabrication of seawater-resistant equipment including ship hulls, propellers, and desalination systems.

-

Chemical Processing: Construction of corrosion-resistant piping, tanks, and heat exchangers handling acidic and aggressive media.

-

Medical Devices: Production of implantable devices, surgical tools, and prosthetics requiring biocompatibility and sterilization durability.

-

Energy Sector: Welding components in power plants, turbines, and oil & gas exploration requiring heat resistance and strength.

-

Sports and Consumer Goods: Manufacturing of lightweight, strong bicycle frames, golf clubs, and high-performance sporting equipment.

|

|

|

|

|

|

Working Environment for Titanium Welding Rods

Titanium Welding Rods excel in challenging environments:

-

Exposure to seawater and saline atmospheres.

-

Acidic and oxidizing chemical atmospheres.

-

High-temperature conditions up to 400°C and beyond for specific alloy grades.

-

High-stress structural joints subject to fatigue and vibration.

-

Sterile and biohazard-sensitive environments requiring biocompatible materials.

Our rods maintain integrity and strength across these conditions, reducing maintenance and replacement costs.

Customization Options for Titanium Welding Rods

At Shaanxi CXMET, we understand that every project has unique requirements. Therefore, we offer tailored customization services, including:

-

Customized rod diameters and lengths.

-

Special alloy grades based on application needs.

-

Pre-cut packaging for automated welding processes.

-

Certification and traceability documents as per client or industry standards.

-

Collaborative product development for new material combinations and welding technologies.

Major Advantages of Our Titanium Welding Rods

-

Unmatched Material Quality: We use top-grade titanium sourced from reliable suppliers, ensuring purity and consistent performance.

-

Advanced Manufacturing Equipment: State-of-the-art melting, forging, and processing facilities guarantee tight dimensional tolerances and excellent surface finish.

-

Professional Technical Support: Over 80 expert technicians provide guidance on material selection, welding parameters, and post-weld treatments.

-

Global Market Orientation: Products designed to meet or exceed international standards such as ASTM, AMS, ISO, and EN.

-

Competitive Pricing: Cost-effective production methods without compromising quality.

-

Environmental Friendliness: Titanium’s inertness ensures no harmful emissions or byproducts during welding and use.

-

Comprehensive After-Sales Service: From consultation to delivery and after-sales follow-up, we ensure client satisfaction.

Packaging and Logistics

To ensure safe delivery, our Titanium Welding Rods are carefully packaged:

-

Rods are bundled securely to avoid bending and surface damage.

-

Protective wrapping prevents contamination and corrosion during transit.

-

Custom packaging options are available, including wooden crates and reinforced cartons for bulk orders.

-

We cooperate with reliable global logistics partners to offer timely shipping to all major ports worldwide.

-

Clear labeling and documentation are provided to facilitate smooth customs clearance.

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Shaanxi CXMET Technology Co., Ltd.

Since 2005, Shaanxi CXMET Technology Co., Ltd. has been a trusted name in the titanium and specialty metals industry. Our company is headquartered in the renowned "China Titanium Valley," covering an area of 50,000 square meters with registered capital of 10 million USD.

Our Enterprise Strengths:

-

Extensive Product Range: Covering titanium, nickel, tantalum, niobium, tungsten, molybdenum, zirconium, and their alloys.

-

Outstanding Production & Processing Capabilities: Equipped with modern facilities and expert technicians.

-

Continuous Innovation: We actively develop new materials and products tailored for international markets.

-

Technological Leadership: Investing in R&D and collaborating with global experts.

-

Customized Solutions: Tailored products and services to meet specific customer demands.

Corporate Culture and Vision:

-

We operate with integrity as our foundation, adhering to legal standards and building trust.

-

We encourage development through teamwork, continuous learning, and adapting to market changes.

-

We foster innovation, empowering our team to break new ground and set industry benchmarks.

-

We pursue excellence in service, ensuring high-quality products and superior customer experience.

Our mission is to create value for customers, generate business benefits, and provide growth platforms for employees. Our vision is to build exceptional quality and innovate boldly to shape the future of the titanium industry.

FAQ

Q1: What welding processes are suitable for your Titanium Welding Rods?

A1: Our rods are primarily designed for TIG (GTAW) and plasma welding but can also be used in other precise welding applications requiring high-quality titanium filler metals.

Q2: Can you provide custom diameters or lengths for the rods?

A2: Yes, we offer full customization to meet your specific welding needs.

Q3: Do you provide material certification?

A3: All our rods come with full chemical and mechanical test reports complying with ASTM, AMS, or other requested standards.

Q4: How do you ensure the quality of the welding rods?

A4: We maintain rigorous quality control through every production stage, including raw material inspection, melting, forging, and final testing.

Q5: What is the typical lead time for orders?

A5: Lead time depends on order size and customization but generally ranges from 2 to 4 weeks.

Contact Us

Discover the best titanium welding solutions for your projects. Reach out to Shaanxi CXMET Technology Co., Ltd. for competitive quotes, technical consultation, and tailored solutions.

Email: sales@cxmet.com

Tel & WhatsApp: +86 158 9119 2169

hotTags:Titanium Welding Rod,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

Grade 6 Titanium Bar

Product Name: Grade 6 titanium

Brand: CXMET

Place Of Origin: China

Material: Titanium

Surface: Polished/Pickling

Type: Round

Shape: Round bar

Standard: ASTM B348, ASTM F136, AMS 4920

Titanium Hex Bar For Sale

Brand: CXMET

Place Of Origin: China

Material: Pure titanium titanium alloy

Grade: Gr1,Gr2,Gr5,Gr7,Gr12,etc

Color: Ti Natural

Applacation: Industry Diameter:60-50mm

Length <6000mm(nomal size)

Gr9 Titanium Bar

Brand: CXMET

Place Of Origin: China

Grade: Titanium GR-9

Standard: ASTM B348 / ASME SB348, AMS 4976, AMS 4956

Type: Seamless / Welded / Fabricated / LSAW Pipes

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

Ti13Nb13Zr Rod

Brand: CXMET

Place Of Origin: China

Classification:Round/Square/Hexagon

Standard:ASTM B348,ASTM F67,ASTM F136,ASME SB348

Grade: Gr1-Gr7,Gr5,Gr5 Eli,Gr12

Size: Dia(0.8mm-100mm)*Length(≤3000mm)

Processing Method:Forging/Extrusion/Rolling/Cold drawing

Gr12 Titanium Square Bar

Brand: CXMET

Place Of Origin: China Shape:Square

Grade: Gr12

Standard: ASTM B348

Technique: Rolling

Certificates: ISO 9001:2015

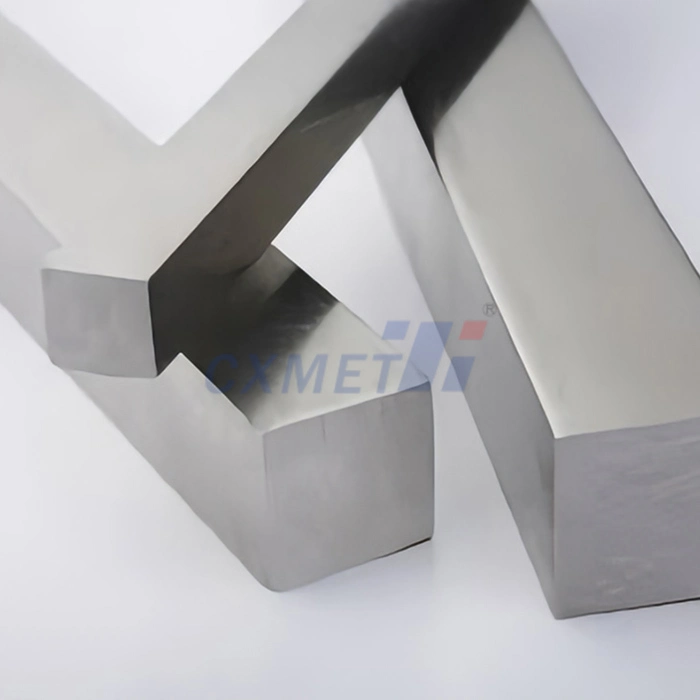

Titanium Square Bar

Brand: CXMET

Place Of Origin: China

Material: GR1,GR2,GR3,GR4,GR5,6AL4VEli,GR7,GR9,GR12,GR23

Standards: ASTM B348,ASTM F67,ASTM F136

Surface : Polished bright,machined ,grind

Supply condition: Hot rolling ,cold drawing ,annealed

Shape: Square

titanium Grade 4 Round Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial, Medical

Technique: Cold Drawn/Hot Rolled/Forged

Grade: Gr4

Shape: Round/Square/Hexagonal/Wire

Diameter: 1-450 mm

.webp)

titanium Grade 2 Round Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial, Medical

Technique: Hot Rolled

Grade: GR2

Shape: Round

Transport Package: As Your Requirements