- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

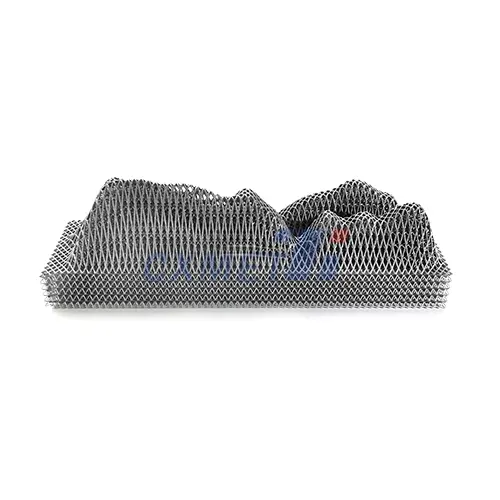

Titanium anode for industrial wastewater treatment

Place Of Origin:China

Base Material Ti (Gr1, Gr2)

Coating Material IrO2, RuO2

Coating Thickness 820μm

Lifespan 10000-18000 Hours

Current Density <300A/m2

Salt Concentration 0.30.5%

Size: Customizable.

Packaging: standard export wooden cases or according to your requirements

Shipping: Support Air freight, Sea freight, Express freight

ABOUT US

Shaanxi CXMET Technology Co., Ltd. is a leading manufacturer and supplier of high-quality titanium anodes for industrial wastewater treatment. With over 20 years of experience, we offer cutting-edge solutions that combine durability, efficiency, and cost-effectiveness. Our titanium anodes are designed to meet the most demanding requirements in wastewater treatment applications, ensuring superior performance and compliance with environmental regulations

Product Introduction

Our titanium anodes for industrial wastewater treatment are engineered to excel in electrochemical oxidation processes, effectively removing contaminants and pollutants from industrial effluents. These anodes are the cornerstone of advanced wastewater treatment systems, providing a reliable and eco-friendly solution for various industries.

Key Features and Benefits

- Superior Corrosion Resistance: Our titanium anodes withstand harsh chemical environments, ensuring longevity and reduced maintenance costs.

- High Catalytic Efficiency: Engineered for optimal electrochemical performance, maximizing contaminant removal rates.

- Energy Efficiency: Designed to operate at lower voltages, reducing overall energy consumption and operational costs.

- Versatility: Suitable for a wide range of industrial applications, from chemical processing to textile manufacturing.

- Customizable Coatings: Available with various mixed metal oxide (MMO) coatings to enhance specific treatment processes.

OEM and Customization Services: Customized Geometries and Exact Dimensions

At Shaanxi CXMET, we understand that every wastewater treatment system is unique. Our OEM services allow us to tailor titanium anodes to your exact specifications:

- Custom dimensions and shapes to fit your existing infrastructure

- Specialized coatings for targeted pollutant removal

- Integrated designs for seamless installation in your treatment systems

Product Features

- Robust titanium substrate for extended service life

- Advanced MMO coatings for enhanced catalytic activity

- Low overpotential for efficient electrochemical reactions

- Uniform current distribution for consistent treatment

- Resistant to fouling and scaling for reduced maintenance

Technical Specifications

- Material: Grade 1 or Grade 2 Titanium

- Coating Options: IrO2, RuO2, Ta2O5, or custom blends

- Standard Sizes: 1000mm x 500mm x 1mm (customizable)

- Current Density: Up to 10,000 A/m²

- Operating Temperature: -10°C to 95°C

- pH Range: 0-14

Applications and Industries

Our titanium anodes for industrial wastewater treatment find applications across various sectors:

- Chemical Manufacturing: Treating complex chemical effluents

- Electroplating: Removing heavy metals and toxic compounds

- Textile Industry: Decolorization and organic pollutant removal

- Oil & Gas: Produced water treatment and hydrocarbon removal

- Pharmaceuticals: API and organic contaminant degradation

- Municipal Wastewater: Advanced oxidation processes for micropollutants

|

|

|

|

|

|

Manufacturing Process

Our titanium anodes undergo a rigorous manufacturing process:

- Titanium sheet selection and quality inspection

- Precision cutting and shaping

- Surface preparation and etching

- Application of proprietary MMO coatings

- Controlled thermal treatment for coating adhesion

- Final quality control and performance testing

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Us

High Quality: Only ASTM-certified raw materials

Advanced Equipment: Precision coating and welding machinery

Professional Team: 80+ skilled engineers and technicians

One-Stop Solution: From design to export logistics

Global Reach: Experience in 40+ export countries

Responsive Service: Fast quoting and technical support

OEM Services We provide full OEM/ODM support. Whether you require custom ribbon width, coating thickness, or special connectors, Shaanxi CXMET Technology Co., Ltd. can tailor the product to meet your exact application requirements.

FAQs

Q: What is the typical lifespan of your titanium anodes?

A: Under normal operating conditions, our anodes can last 5-10 years, depending on the application and maintenance.

Q: Can your anodes be used in seawater applications?

A: Yes, we offer specialized coatings designed for chlorine evolution in seawater environments.

Q: Do you provide installation support?

A: We offer technical guidance for installation and can recommend certified partners for on-site services.

Contact Us

Ready to upgrade your industrial wastewater treatment system with our advanced titanium anodes? Contact our expert team today:

Email: sales@cxmet.com

Discover how Shaanxi CXMET's titanium anodes can revolutionize your wastewater treatment processes, ensuring environmental compliance and operational efficiency.

hotTags:Titanium anode for industrial wastewater treatment,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

_1768269791782.png)