- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

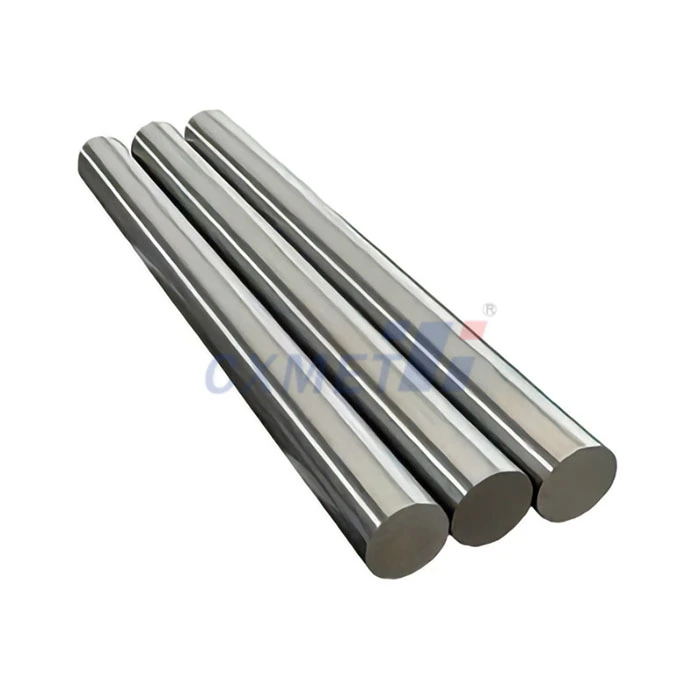

High Quality Gr1 Pure Titanium Bar

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Cold Rolled

Grade: GR1

Shape: Round

Transport Package: As Your Requirements

Premium Titanium Rods for Corrosion-Resistant Applications

Shaanxi CXMET Technology Co., Ltd. is proud to present its High Quality Gr1 Pure Titanium Bar, a top-tier solution for demanding industries requiring lightweight strength, exceptional corrosion resistance, and superior biocompatibility. As one of the softest and most formable grades of commercial pure titanium, Gr1 titanium bars offer a perfect combination of performance and versatility, ideal for chemical processing, marine structures, medical applications, and more.

Crafted using advanced melting and forging techniques, our Gr1 titanium rods meet the highest international standards. With over 20 years of metallurgical expertise, we serve global customers with consistency, reliability, and engineering excellence.

Features of High Quality Gr1 Pure Titanium Bar

-

Extremely High Corrosion Resistance: Outstanding protection in oxidizing and reducing environments including acids, alkalis, and seawater.

-

Excellent Ductility and Workability: Ideal for forming, bending, and deep drawing applications.

-

Superior Weldability: Smooth and defect-free joints when used in structural or piping systems.

-

Lightweight with High Specific Strength: Low density (4.51 g/cm³) makes it suitable for weight-sensitive industries.

-

Biocompatibility: Non-toxic and inert, making it perfect for surgical implants and medical equipment.

-

Thermal Stability: Can operate reliably in temperatures ranging from cryogenic to 400°C.

Specifications of High Quality Gr1 Pure Titanium Bar

| Property | Value |

|---|---|

| Grade | Gr1 (Commercially Pure Titanium) |

| Purity | ≥ 99.5% Titanium |

| Standard Compliance | ASTM B348, ASTM F67, AMS 4921 |

| Diameter Range | 2 mm – 300 mm |

| Length Range | ≤ 6000 mm (Customizable) |

| Density | 4.51 g/cm³ |

| Tensile Strength | ≥ 240 MPa |

| Yield Strength | ≥ 170 MPa |

| Elongation | ≥ 24% |

| Surface Finish | Polished / Pickled / Sandblasted |

| Tolerance | h9–h11 (ISO standard or custom) |

| Certification | EN10204 3.1 / 3.2, ISO, SGS, etc. |

|

|

|

|

Applications of High Quality Gr1 Pure Titanium Bar

Gr1 titanium bars are widely adopted in sectors where corrosion, bio-compatibility, and weight savings are mission-critical:

-

Chemical and Petrochemical Industry: Reactors, heat exchangers, piping, and storage tanks

-

Medical Industry: Bone screws, dental implants, and surgical tools

-

Marine and Offshore Engineering: Propeller shafts, seawater desalination systems

-

Aerospace: Ductwork and non-load bearing components

-

Electronics and Vacuum Applications: Coating materials and electronic parts

-

Energy Sector: Fuel cells, power station condensers, and nuclear power plant components

|

|

|

|

|

|

Suitable Working Environments for Gr1 Titanium Rods

-

Highly corrosive atmospheres

-

Acidic and alkaline chemical exposure

-

Seawater and salt spray conditions

-

Cleanroom and vacuum environments

-

Cryogenic and high-temperature exposure

-

Biomedical implantation and surgical environments

Customization Options for Gr1 Titanium Bar

We offer full customization services to meet the exact technical and industrial needs of our clients:

-

Custom Dimensions: Tailor-made diameters and lengths to fit unique specifications

-

Surface Treatments: Pickled, ground, mirror polish, and shot-blasted finishes

-

Machining Services: Turning, milling, and threading to deliver ready-to-use components

-

OEM and ODM Support: Design and manufacture according to provided drawings or requirements

-

Small Batch to Mass Production: Flexible production quantities from prototyping to bulk orders

Key Advantages of Gr1 Titanium Bars from CXMET

-

Guaranteed Material Purity: Over 99.5% pure titanium content verified by independent labs

-

Unmatched Corrosion Resistance: Performs reliably in harsh, corrosive environments

-

Soft and Formable: Perfect for applications needing high ductility

-

Long Lifespan: Outstanding fatigue and erosion resistance

-

Non-Magnetic and Biocompatible: Suitable for medical and electronic use

-

Precision Tolerances: Manufactured using CNC and ISO-controlled processes

-

Fast Delivery: Efficient supply chain and on-time shipment worldwide

Packaging and Logistics

Every Gr1 titanium bar is carefully packed to ensure safe global delivery:

-

Packaging: PE wrapping, foam cushioning, and plywood crates or steel frames

-

Labeling: Each product marked with heat number, grade, and dimensions for traceability

-

Logistics: We ship globally via air, sea, and express with full customs documentation

-

Inspection Reports: Third-party testing (SGS, TUV) and mill certificates upon request

|

|

|

|

Company Overview

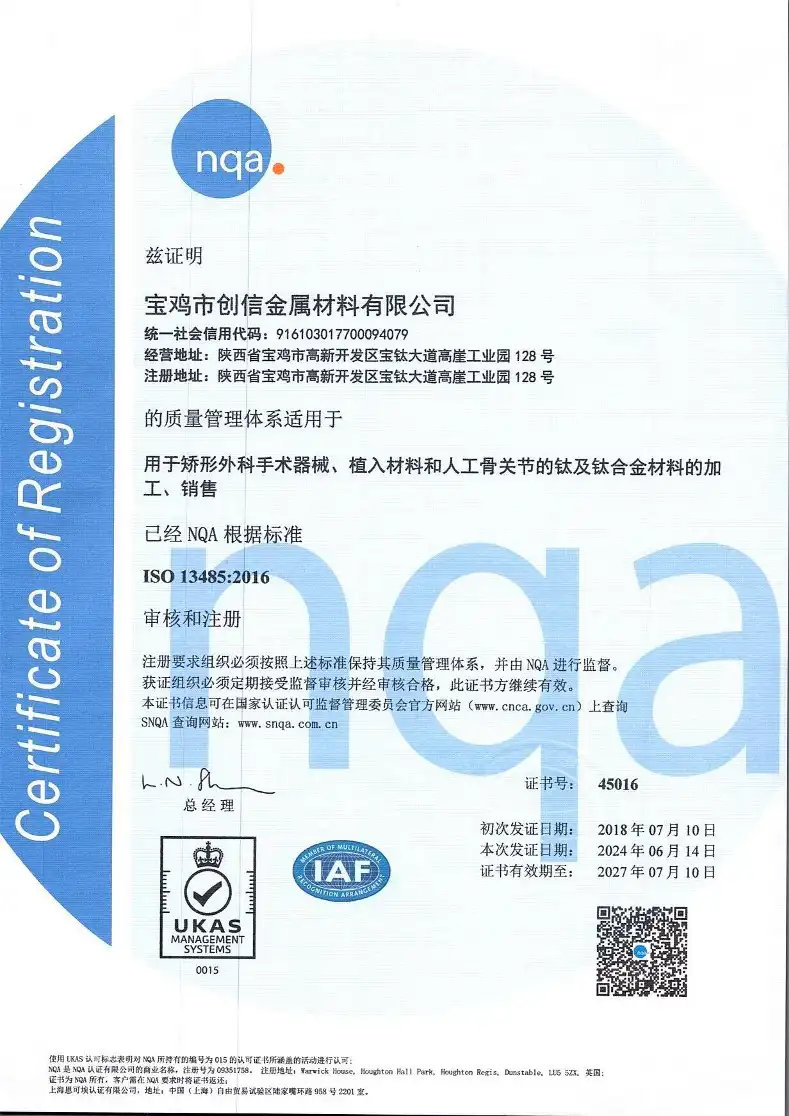

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

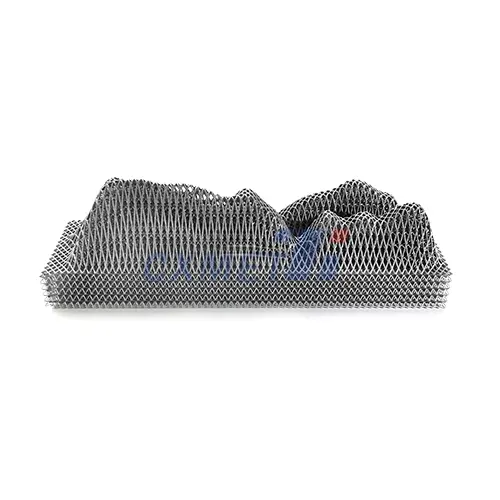

Main Products

Why Choose Shaanxi CXMET Technology Co., Ltd.

Shaanxi CXMET Technology Co., Ltd. is a global leader in non-ferrous and refractory metals. Established in 2005 with a registered capital of 10 million, our facility spans 50000 square meters in Baoji — known as “China Titanium Valley”.

Our Strengths:

-

Extensive Product Range: From titanium and nickel to tantalum, molybdenum, zirconium, and beyond

-

Advanced Processing Capabilities: Forging, rolling, CNC machining, and vacuum annealing

-

R&D and Innovation Driven: Dedicated to developing high-performance materials and custom solutions

-

Global Service Reach: Our products serve industries in over 40 countries

-

Quality First: ISO 9001 certified with complete testing and quality assurance systems

-

Expert Technical Team: Over 80 engineers and technicians with deep industry experience

-

Customer-Centric Philosophy: Fast response, customization, and full after-sales support

At CXMET, integrity, innovation, and excellence form the core of our business culture. We aim to create long-term value for our partners, offering reliable quality and technical expertise.

FAQ

Q1: What certifications do your Gr1 titanium bars carry?

A1: All our bars comply with ASTM B348, ASTM F67, and can be certified by ISO, SGS, and other international standards.

Q2: Can you provide customized sizes or shapes?

A2: Yes, we support full customization including sizes, tolerances, and surface finishes.

Q3: What is the minimum order quantity (MOQ)?

A3: We accept both small quantities for testing and large orders for production. MOQ can be negotiated.

Q4: How long does delivery take?

A4: For standard sizes, lead time is typically 7–15 working days. Custom orders may take 15–25 days.

Q5: Do you offer third-party inspection reports?

A5: Yes, we can provide inspection reports from SGS, BV, or customer-designated agencies.

Contact Us

Partner with Shaanxi CXMET Technology Co., Ltd. for your next titanium requirement. We’re here to support your business with technical expertise, dependable service, and premium quality materials.

Email: sales@cxmet.com

Tel & WhatsApp: +86 15891192169

Let us help you source the High Quality Gr1 Pure Titanium Bar you can trust. Contact us now for a detailed quotation and tailored solution.

hotTags:High Quality Gr1 Pure Titanium Bar,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

Grade 6 Titanium Bar

Product Name: Grade 6 titanium

Brand: CXMET

Place Of Origin: China

Material: Titanium

Surface: Polished/Pickling

Type: Round

Shape: Round bar

Standard: ASTM B348, ASTM F136, AMS 4920

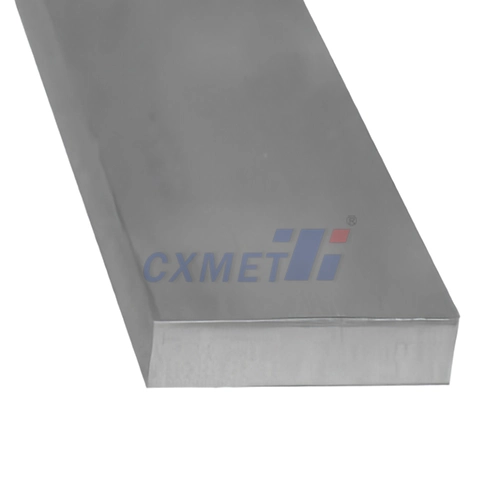

Titanium Rectangular Bar

Brand: CXMET

Place Of Origin: China

Thickness:4.5

Width: 4.75

Max Length:144

Alloy: 6AL-4V Grade 5

MTR Availability: Yes

Material: Titanium

Shape: Bar-Rectangle

Titanium Hex Bar For Sale

Brand: CXMET

Place Of Origin: China

Material: Pure titanium titanium alloy

Grade: Gr1,Gr2,Gr5,Gr7,Gr12,etc

Color: Ti Natural

Applacation: Industry Diameter:60-50mm

Length <6000mm(nomal size)

Gr9 Titanium Bar

Brand: CXMET

Place Of Origin: China

Grade: Titanium GR-9

Standard: ASTM B348 / ASME SB348, AMS 4976, AMS 4956

Type: Seamless / Welded / Fabricated / LSAW Pipes

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

Gr5 Titanium Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Hot Rolled

Shape: Round

Length: 50-6000mm

Dia 10mm Titanium Rod In Medical

Brand: CXMET

Place Of Origin: China

Shape: Round

Grade: Gr5

Weight: According the dimension

Processing Service :Rolling, Ground

Material: titanium

Surface :Treatment Ground

MOQ: 10 KG

Standard :ASTM B348 ASTM F136

Package: Standard Wooden Case

Stock Size: Dia3-40mm Titanium Rod

tianium Alloy 6Al-2Sn-4Zr-6Mo Round Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial, Medical

Technique: Hot Rolled

Shape: Round

Classification: Commercially Pure

titanium Grade 4 Round Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial, Medical

Technique: Cold Drawn/Hot Rolled/Forged

Grade: Gr4

Shape: Round/Square/Hexagonal/Wire

Diameter: 1-450 mm