- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

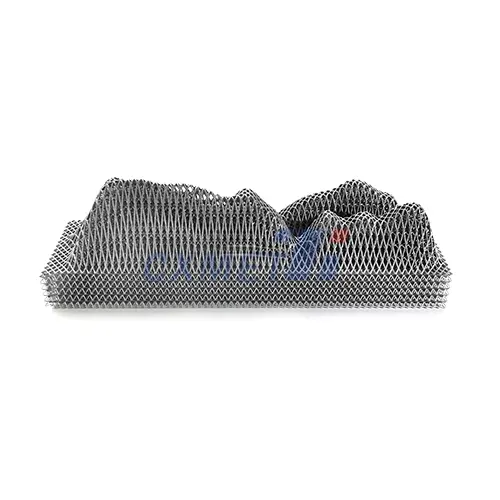

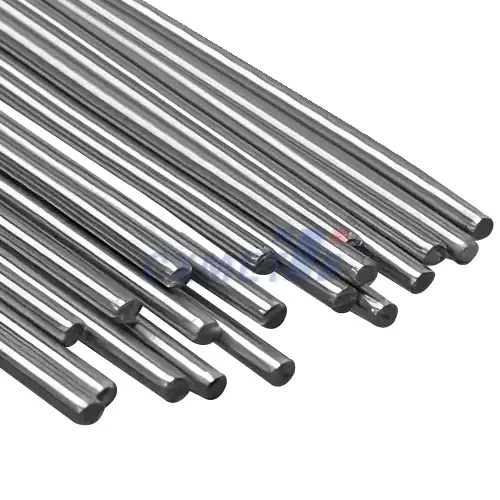

tianium Alloy 6Al-2Sn-4Zr-6Mo Round Bar

Place Of Origin: China

Type: Titanium Bars

Application: Industrial, Medical

Technique: Hot Rolled

Shape: Round

Classification: Commercially Pure

Product Introduction: Titanium Alloy 6Al-2Sn-4Zr-6Mo Round Bar

Shaanxi CXMET Technology Co., Ltd. proudly offers Titanium Alloy 6Al-2Sn-4Zr-6Mo Round Bars, engineered for high-performance applications demanding exceptional strength, heat resistance, and structural stability. Known by its industry designation as Ti-6-2-4-6, this near-alpha titanium alloy is highly regarded for use in aerospace, high-temperature chemical environments, and advanced engineering sectors.

Manufactured with precision from vacuum arc melted (VAR) or triple-melted ingots, our Ti-6-2-4-6 round bars offer outstanding performance at elevated temperatures and prolonged stress exposure. This grade delivers a unique combination of mechanical integrity, excellent creep resistance, and superior oxidation resistance—making it a strategic choice for aerospace jet engines and industrial gas turbines.

Features of Titanium Alloy 6Al-2Sn-4Zr-6Mo Round Bar

-

Excellent High-Temperature Strength: Maintains mechanical properties up to 550°C (1022°F).

-

Superior Oxidation and Creep Resistance: Reliable under long-term stress and temperature exposure.

-

Good Weldability and Formability: Adaptable to various manufacturing techniques.

-

High Specific Strength: Outstanding strength-to-weight ratio.

-

Corrosion Resistance: Suitable for marine and chemical processing environments.

Specifications

| Parameter | Value |

|---|---|

| Alloy Grade | Ti-6Al-2Sn-4Zr-6Mo |

| Product Type | Round Bar |

| Standard | AMS 4981 / ASTM B348 / MIL-T-9047 |

| Diameter Range | 6 mm to 200 mm |

| Length | Up to 6000 mm (customizable) |

| Tensile Strength | ≥ 1030 MPa |

| Yield Strength | ≥ 965 MPa |

| Elongation | ≥ 10% |

| Density | 4.54 g/cm3 |

| Heat Treatment Condition | Annealed / Solution Treated / Aged |

Applications

Titanium Alloy 6Al-2Sn-4Zr-6Mo Round Bars are ideal for:

-

Aerospace components: Engine compressor parts, blades, discs, and airframe fasteners

-

Gas turbines: Rotors and casings requiring high creep resistance

-

Military applications: Missile structural elements and high-performance hardware

-

Chemical processing: Equipment exposed to high temperature and corrosive environments

-

Marine engineering: High-load and temperature-sensitive hardware

|

|

|

|

|

|

Working Environment

Ti-6-2-4-6 round bars are specifically designed for challenging environments:

-

High-temperature applications: Sustains properties up to 550°C

-

Stress-loaded structural elements: Excellent fatigue and creep resistance

-

Oxidative and corrosive atmospheres: Chemical stability in seawater, acidic gases, and industrial oxidants

-

Vacuum or inert atmospheres: Ideal for aerospace and high-end manufacturing

Customization Options

Shaanxi CXMET Technology Co., Ltd. offers full customization services:

-

Custom diameter and length

-

Heat treatment: annealed, solution treated, aged

-

Surface finish: polished, turned, ground

-

Ultrasonic testing and NDT per customer requirement

-

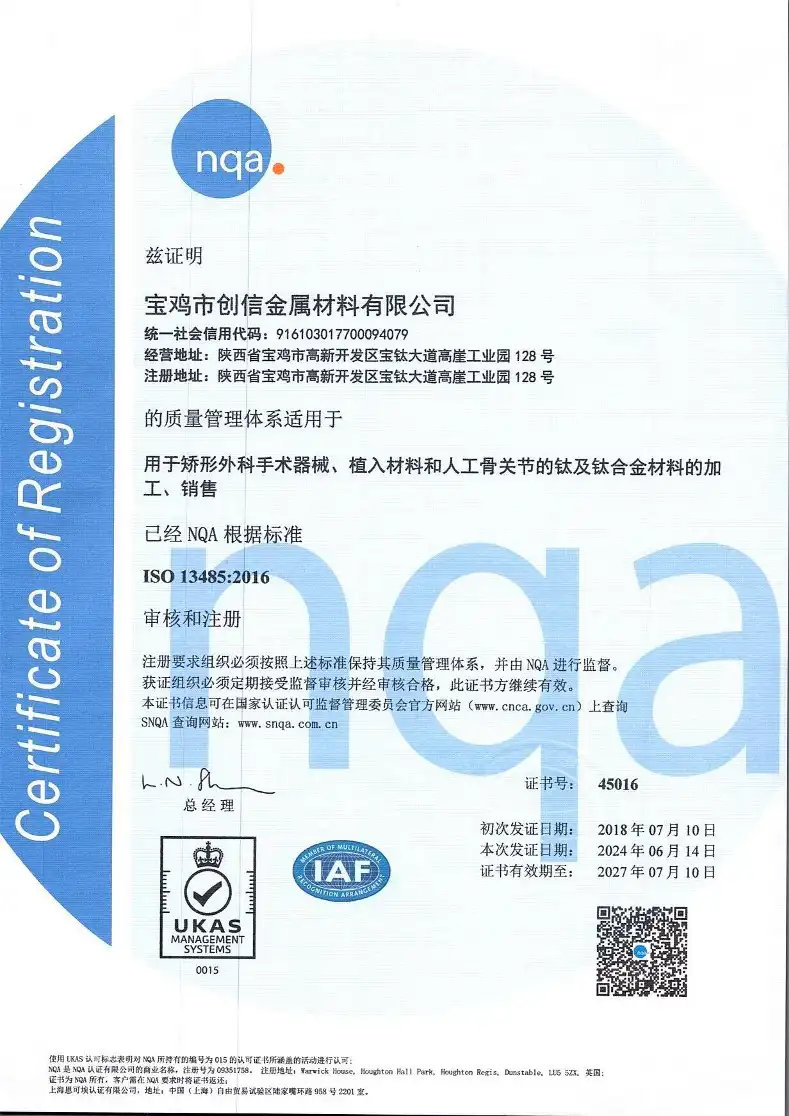

Certification: EN 10204 3.1, ISO, ASTM, and aerospace standards compliance

Key Advantages

-

Unmatched Quality: Stringent QC with in-house inspection

-

High Temperature Performance: Stable mechanical properties at elevated temperatures

-

Comprehensive Technical Support: Expert engineering assistance and material selection guidance

-

Global Delivery: Fast production turnaround and international shipping

-

One-Stop Sourcing: From raw material to finished components

Packaging and Logistics

Each Titanium Alloy 6Al-2Sn-4Zr-6Mo Round Bar is carefully packed to prevent damage during transit:

-

Standard packaging: Plastic film + wooden crate

-

Moisture-proof, anti-rust protection

-

Custom labeling with heat number and full traceability

-

Global shipping via air, sea, or express courier

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Us

Shaanxi CXMET Technology Co., Ltd. is a leading force in the non-ferrous and refractory metal industry:

-

Extensive Product Range: Titanium, nickel, tantalum, niobium, tungsten, molybdenum, zirconium & alloys

-

Advanced Equipment: Modern forging, rolling, machining, and inspection facilities

-

Continuous Innovation: Dedicated R&D team developing new materials and solutions

-

Customization Expertise: Tailored solutions for diverse industrial needs

-

Corporate Strength: Founded in 2005, covering 50,000 m², located in "China Titanium Valley"

-

Professional Team: Over 80 experienced technical staff

-

Global Reach: Exported to 50+ countries across aerospace, chemical, marine, medical, and energy industries

-

Corporate Culture: Integrity, development, innovation, and service excellence

FAQ

Q1: What is the heat resistance of Ti-6-2-4-6 round bar? A1: It performs reliably up to 550°C (1022°F) with excellent creep resistance.

Q2: Can I order small trial quantities? A2: Yes, sample orders and small batch customization are available.

Q3: Do you offer machining and secondary processing? A3: Absolutely. We offer cutting, turning, grinding, and CNC services per customer drawings.

Q4: What inspection methods do you use? A4: Ultrasonic testing, tensile testing, chemical composition analysis, and dimensional inspection.

Q5: How fast is your delivery time? A5: Standard bars ship in 7–10 working days; custom items within 15–20 days depending on specs.

Contact Us

Email: sales@cxmet.com

Tel & WhatsApp: +86 15891192169

Reach out now to get your personalized quotation, technical consultation, or explore OEM cooperation opportunities.

hotTags:tianium Alloy 6Al-2Sn-4Zr-6Mo Round Bar,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

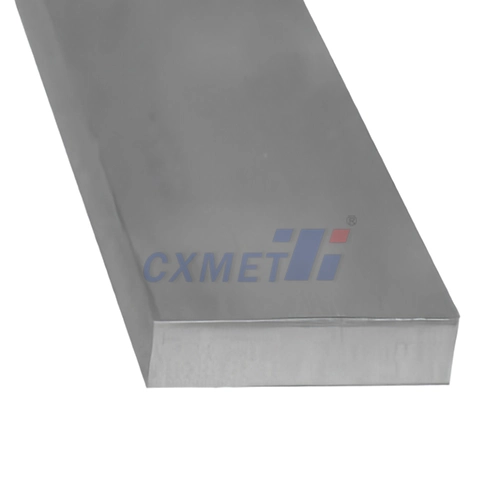

Titanium Rectangular Bar

Brand: CXMET

Place Of Origin: China

Thickness:4.5

Width: 4.75

Max Length:144

Alloy: 6AL-4V Grade 5

MTR Availability: Yes

Material: Titanium

Shape: Bar-Rectangle

Nitinol Bar Stock

Brand: CXMET

Place Of Origin: China

Specification: ASTM F2063

Af Temperature -10°C to 120°C

Size >0.2” Diameter

Surface: Black, Pickled, Polished

Other types: Bar, rectangular bar and other customized shape

Gr5 Titanium Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Hot Rolled

Shape: Round

Length: 50-6000mm

Dia 10mm Titanium Rod In Medical

Brand: CXMET

Place Of Origin: China

Shape: Round

Grade: Gr5

Weight: According the dimension

Processing Service :Rolling, Ground

Material: titanium

Surface :Treatment Ground

MOQ: 10 KG

Standard :ASTM B348 ASTM F136

Package: Standard Wooden Case

Stock Size: Dia3-40mm Titanium Rod

Ti-13Nb-13Zr Titanium Rod

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Cold Rolled

Grade: Gr1 Gr2

Shape: Round

Density: 4.5g/cm3

Gr23 Ti 6AL4V Eli Medical Titanium Bar

Brand: CXMET

Place Of Origin: China

Grade: Gr23 Ti6AL4V Eli

Standard: ASTM F136

Specification: Dia4~100mm*(1000~3000)mm

Technique: Cold Rolling/Hot Rolling

Surface: Pickling/Polished

Application: industrial

High Standard Gr12 Titanium Alloy Bar

Brand: CXMET

Place Of Origin: China

Gr12 Titanium Alloy Bar/Titanium Sheet/Titanium Tube

Product specification range: Diameter 6-500mm, Length 0.5-30m

Product Specification Range: Thickness 0.5-80mm, length 1-12m, width 0.5-3m

Product Specification Range: OD 6-530mm, wall thickness 0.5-50mm

Length 1-12m

Shape: Round

High Quality Gr1 Pure Titanium Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Cold Rolled

Grade: GR1

Shape: Round

Transport Package: As Your Requirements