- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

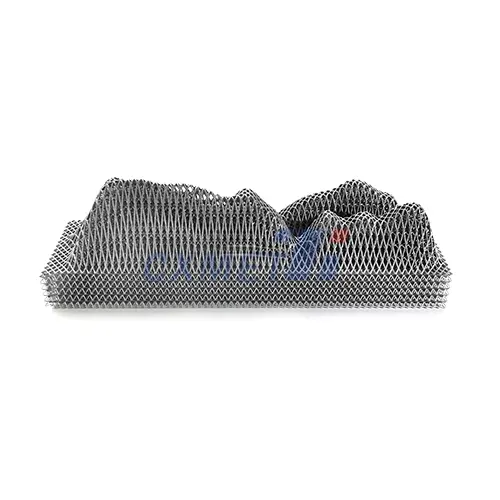

Gr7 Titanium Rod

Place Of Origin: China

Standrd: ASTM B348 ASTM F136 AMS4928 ASTMF1295

Specifaction φ>6mm Length(Max)6000mm

Surface :Bright

Technology: Forging/Rolling

Content of Pb: 0.12---0.25%

Application: Medical, Aviation, Petrochemical, Metallurgy, Electroplating

Vacuum: Coating, Sports and other Industries.

Gr7 Titanium Rod Product Introduction

Shaanxi CXMET Technology Co., Ltd. proudly presents our premium Gr7 Titanium Rod, a highly specialized titanium alloy rod containing 0.2% palladium. Known for its outstanding corrosion resistance in aggressive environments, Gr7 Titanium Rod is an ideal solution for industries requiring materials that withstand strong acidic and chloride-rich conditions. Combining the excellent mechanical properties of commercially pure titanium with enhanced chemical resistance, our Gr7 Titanium Rod serves as a reliable component in chemical processing, marine engineering, and other demanding industrial applications.

Manufactured with stringent quality control and advanced metallurgical techniques, our Gr7 rods ensure superior performance, durability, and reliability. Whether you require small or large diameter rods, customized lengths, or specific surface finishes, Shaanxi CXMET offers tailored solutions to meet your precise requirements.

Features of Gr7 Titanium Rod

-

Excellent Corrosion Resistance: Enhanced by the addition of 0.2% palladium, Gr7 titanium exhibits exceptional resistance to oxidizing acids, especially chlorides, making it superior to Gr2 in harsh chemical environments.

-

Moderate Strength with Good Ductility: Tensile strength around 340 MPa and yield strength near 275 MPa, paired with 20% elongation, provide a balanced combination of strength and flexibility.

-

Lightweight and Durable: Titanium’s low density (approximately 4.5 g/cm³) offers weight reduction advantages compared to steel without compromising strength.

-

High Biocompatibility: While mainly used industrially, Gr7’s biocompatibility allows safe use in some specialized medical environments.

-

Good Weldability and Fabrication: Gr7 rods can be easily machined, welded, and formed for diverse engineering applications.

-

Stable Performance at Elevated Temperatures: Maintains mechanical properties under moderate heat conditions, suitable for industrial processes.

Specifications of Gr7 Titanium Rod

| Property | Value |

|---|---|

| Grade | Gr7 (Titanium + 0.2% Pd) |

| Chemical Composition | Ti + 0.2% Palladium (Pd) |

| Tensile Strength (MPa) | ≥ 340 |

| Yield Strength (MPa) | ≥ 275 |

| Elongation (%) | ≥ 20 |

| Density (g/cm³) | Approx. 4.5 |

| Typical Diameter Range | 6 mm to 200 mm |

| Length | Customized, standard up to 6 meters |

| Surface Finish | Mill finish, polished, or as requested |

|

|

Applications of Gr7 Titanium Rod

Gr7 Titanium Rod is widely employed in sectors where chemical resistance and mechanical integrity are paramount. Key application areas include:

-

Chemical Processing Equipment: Ideal for heat exchangers, reactors, and piping in highly corrosive environments containing chlorides or oxidizing acids.

-

Marine Engineering: Used in seawater systems such as desalination plants, offshore platforms, and ship components due to excellent resistance against seawater corrosion.

-

Power Generation: Components exposed to harsh chemical conditions in power plants, including condensers and cooling systems.

-

Petroleum Industry: Suitable for refinery equipment and pipelines subject to corrosive fluids.

-

Pharmaceutical and Food Industry: When cleanliness and corrosion resistance are required under acidic conditions.

-

Aerospace and Automotive: Where lightweight, corrosion-resistant materials improve component longevity and performance.

-

Vacuum and Coating Technology: Due to high purity and corrosion resistance.

|

|

|

|

|

|

Working Environment for Gr7 Titanium Rod

Gr7 Titanium Rod thrives in environments characterized by:

-

Strong acidic conditions, especially hydrochloric acid and other chlorides

-

Oxidizing environments where standard titanium grades may degrade

-

Seawater and marine atmospheres with high salt content

-

Moderate to high temperatures up to approximately 400 degrees Celsius without loss of mechanical properties

-

Industrial chemical exposure, including oxidizing agents and highly corrosive solutions

This grade is engineered for reliability where long-term corrosion resistance is critical, significantly extending service life and reducing maintenance frequency.

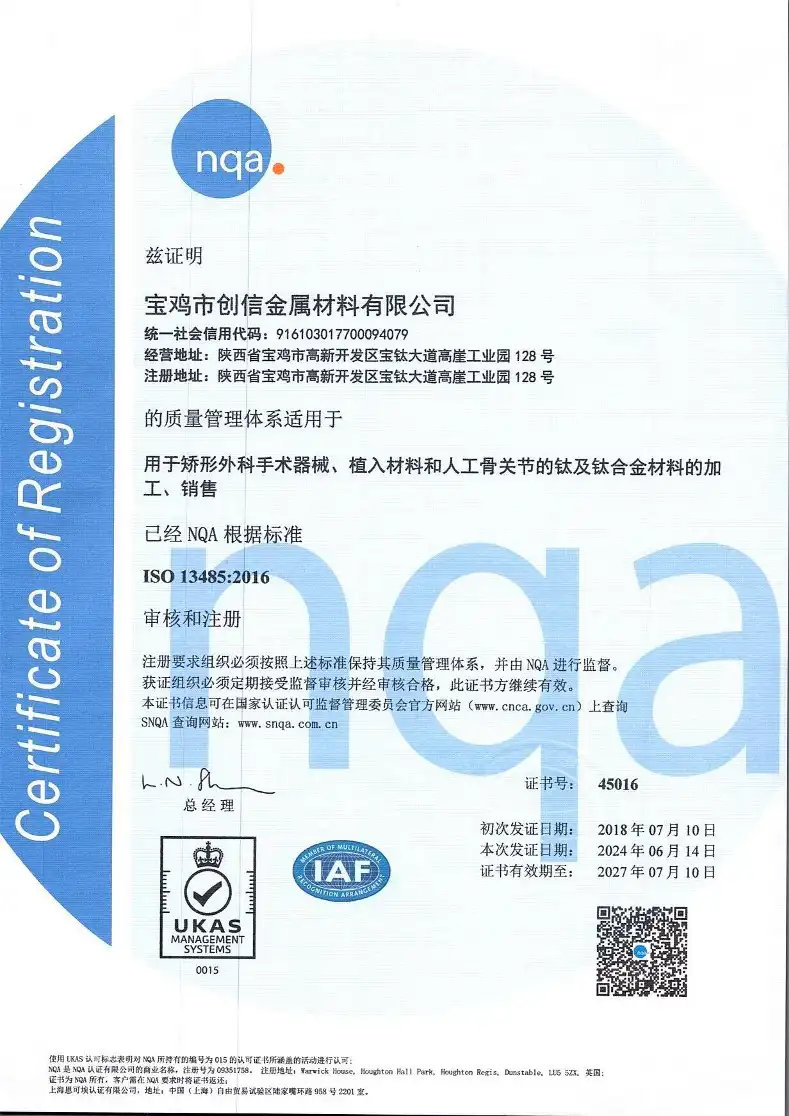

Customization Options for Gr7 Titanium Rod

At Shaanxi CXMET, we understand that different projects require unique solutions. We offer:

-

Custom rod diameters and lengths to fit your precise engineering needs

-

Special surface treatments such as polishing, grinding, or coating

-

Customized packaging and delivery schedules to align with your project timeline

-

Compliance with international standards and certification tailored to your market

-

OEM services to support your brand and technical specifications

Our flexible manufacturing and processing capabilities ensure your Gr7 Titanium Rod is perfectly suited for your application.

Key Advantages of Gr7 Titanium Rod

-

Superior Corrosion Resistance: The palladium addition dramatically improves resistance against oxidizing acids and chlorides compared to standard commercially pure titanium.

-

Long Service Life: Reduces replacement frequency and lowers lifecycle costs in corrosive environments.

-

High Strength-to-Weight Ratio: Offers significant weight savings over stainless steel and other alloys without sacrificing strength.

-

Low Maintenance: Resistant to fouling and corrosion-related damage, decreasing downtime and repair costs.

-

Environmentally Friendly: Titanium is biocompatible and non-toxic, making it a sustainable choice.

-

Reliable Quality Assurance: Produced with strict control procedures and tested for mechanical and chemical properties.

Packaging and Logistics

We ensure your Gr7 Titanium Rods arrive in perfect condition with:

-

Secure packaging to prevent damage during transportation, using wooden crates or customized containers

-

Clear labeling and documentation for customs clearance and traceability

-

Timely shipment options via air, sea, or express courier based on your location and urgency

-

Professional logistics partnerships ensuring safe and efficient delivery worldwide

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Shaanxi CXMET Technology Co., Ltd.

Company Overview

Founded in 2005 with a registered capital of 10 million RMB, Shaanxi CXMET Technology Co., Ltd. covers 50,000 square meters in the renowned "China Titanium Valley." We specialize in titanium, nickel, tantalum, niobium, tungsten, molybdenum, zirconium, and their alloys. Over two decades, we have established a robust presence with over 80 skilled technicians focused on innovation and quality.

Core Strengths

-

Extensive product range meeting diverse industrial demands

-

Outstanding production and processing capabilities utilizing advanced equipment

-

Continuous innovation leading new product development and technology

-

Strong international market focus with tailored customer solutions

-

Commitment to integrity, development, innovation, and excellent service

Corporate Culture

Our business philosophy centers on integrity, development, innovation, and service excellence. We maintain honesty and transparency, fostering trust with clients and partners worldwide. Our mission is to create value for customers, drive business success, and support employee growth. We strive to shape the future of the titanium industry through sincere quality and creative wisdom.

FAQ

Q1: What is the main difference between Gr7 and Gr2 titanium rods?

A: Gr7 contains 0.2% palladium, enhancing corrosion resistance in oxidizing and chloride environments compared to Gr2, which is commercially pure titanium without palladium.

Q2: Can Gr7 Titanium Rod be welded?

A: Yes, Gr7 titanium rods have good weldability using standard titanium welding techniques such as TIG and laser welding.

Q3: What sizes can you provide for Gr7 rods?

A: We offer diameters from 6mm to 200mm and custom lengths up to 6 meters or as per customer requirements.

Q4: Is Gr7 suitable for seawater applications?

A: Absolutely. Gr7’s corrosion resistance makes it ideal for marine and seawater systems.

Q5: Do you provide material certification?

A: Yes, we supply comprehensive test reports and certifications in line with international standards.

Contact Us

Shaanxi CXMET Technology Co., Ltd. warmly welcomes global buyers to discuss your Gr7 Titanium Rod requirements. Our professional team is ready to provide expert advice, custom offers, and prompt delivery.

-

Email: sales@cxmet.com

-

Tel & WhatsApp: +86 15891192169

hotTags:Gr7 Titanium Rod,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

titanium 6Al-4V Grade 5 Round Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Medical

Technique: Hot Rolled

Grade: GR5

Shape: Round

Outer Diameter: 6-200mm

Nitinol Bar Stock

Brand: CXMET

Place Of Origin: China

Specification: ASTM F2063

Af Temperature -10°C to 120°C

Size >0.2” Diameter

Surface: Black, Pickled, Polished

Other types: Bar, rectangular bar and other customized shape

Ti13Nb13Zr Rod

Brand: CXMET

Place Of Origin: China

Classification:Round/Square/Hexagon

Standard:ASTM B348,ASTM F67,ASTM F136,ASME SB348

Grade: Gr1-Gr7,Gr5,Gr5 Eli,Gr12

Size: Dia(0.8mm-100mm)*Length(≤3000mm)

Processing Method:Forging/Extrusion/Rolling/Cold drawing

Gr5 Titanium Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Hot Rolled

Shape: Round

Length: 50-6000mm

Titanium AMS 6242 Rod For Aerospace

Product name: 6al-4v titanium round

bar

Brand: CXMET

Place Of Origin: China

Application:Aerospace

Grade:Gr1

Standard: AMS4928

Density: 4.51g/cm3

Technique: Rolled

Shape: Round

Surface: Polished

Color: Sliver

Certificates: ISO 9001:2015

Titanium Square Bar

Brand: CXMET

Place Of Origin: China

Material: GR1,GR2,GR3,GR4,GR5,6AL4VEli,GR7,GR9,GR12,GR23

Standards: ASTM B348,ASTM F67,ASTM F136

Surface : Polished bright,machined ,grind

Supply condition: Hot rolling ,cold drawing ,annealed

Shape: Square

Titanium Welding Rod

Brand: CXMET

Place Of Origin: China

Grade: Gr1 Gr2 Gr7 Gr5

Ti (Min): 99.6%

Strength: 345MPa

Surface: Pickling Polished

Shape: Spool Coil Straight

Standard: ASTM B863

Certification: ISO9001:2015

Strength: 435MPa

Application: Industrial

High Quality Gr1 Pure Titanium Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Cold Rolled

Grade: GR1

Shape: Round

Transport Package: As Your Requirements