- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

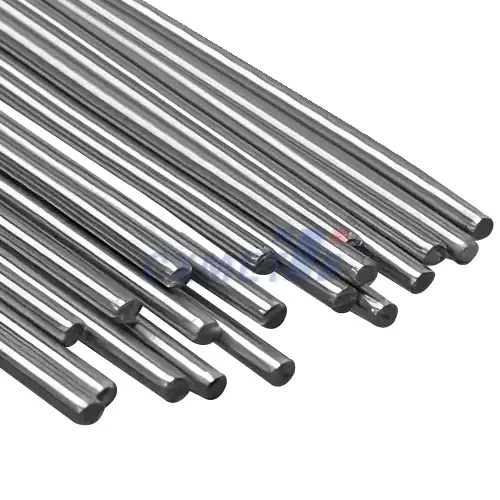

High Standard Gr12 Titanium Alloy Bar

Place Of Origin: China

Gr12 Titanium Alloy Bar/Titanium Sheet/Titanium Tube

Product specification range: Diameter 6-500mm, Length 0.5-30m

Product Specification Range: Thickness 0.5-80mm, length 1-12m, width 0.5-3m

Product Specification Range: OD 6-530mm, wall thickness 0.5-50mm

Length 1-12m

Shape: Round

High Standard Gr12 Titanium Alloy Bar

Shaanxi CXMET Technology Co., Ltd. proudly offers the High Standard Gr12 Titanium Alloy Bar, an industrial-grade α titanium alloy bar designed to meet demanding environments where both corrosion resistance and moderate strength are essential. Gr12, known chemically as Ti-0.3Mo-0.8Ni, is distinguished for its excellent formability, weldability, and corrosion resistance—particularly in mildly reducing and oxidizing conditions.

As one of the premium titanium alloy grades developed for heat exchanger systems and chemical processing applications, the Gr12 Titanium Alloy Bar has become a preferred choice across marine, chemical, power generation, and industrial engineering sectors. With a balanced profile of strength and durability, it offers users a cost-effective and long-lasting solution for components exposed to harsh chemical media or seawater.

Key Features of Gr12 Titanium Alloy Bar

-

Superior corrosion resistance in acidic, chloride-rich, and oxidizing environments

-

High mechanical strength with stable performance across various industrial temperatures

-

Excellent weldability and formability for customized fabrication and integration

-

Remarkably resistant to crevice corrosion and stress corrosion cracking

-

Lightweight structure for ease of transport and structural efficiency

-

Long service life even under cyclic stress or chemical exposure

-

Biocompatibility with non-toxic and environmentally friendly properties

Specifications of Gr12 Titanium Alloy Bar

| Property | Value |

|---|---|

| Grade | Gr12 (Ti-0.3Mo-0.8Ni) |

| Standard | ASTM B348, ASTM F67, AMS 4955 |

| Diameter Range | 6 mm to 200 mm |

| Length | Up to 6000 mm or custom |

| Surface Finish | Polished, Peeled, Ground, Turned |

| Tensile Strength | ≥ 480 MPa |

| Yield Strength | ≥ 345 MPa |

| Elongation | ≥ 18 percent |

| Density | 4.51 g/cm³ |

| Processing Type | Forged, Rolled, Annealed |

| Tolerance | As per ISO 2768 or customer request |

Applications of Gr12 Titanium Alloy Bar

Gr12 Titanium Alloy Bars are widely used in industries that demand both strength and corrosion resistance:

-

Heat exchangers in chemical and petrochemical processing

-

Tubing and piping systems in power plants and refineries

-

Desalination plants and marine equipment

-

Flue gas desulfurization (FGD) systems

-

Industrial condenser systems

-

Chlor-alkali and pulp and paper processing equipment

-

Architectural and structural components exposed to corrosion

|

|

|

|

|

|

Operating Environments for Gr12 Titanium Alloy Bar

Gr12 titanium alloy exhibits stable performance in challenging industrial environments, including:

-

Acidic and mildly reducing chemical media

-

Chloride-rich and seawater conditions

-

Oxidizing environments with varying pH values

-

High-humidity and condensation-prone areas

-

Systems under elevated operational temperatures

This alloy is particularly useful where traditional CP titanium may not be strong enough and where more expensive alloys might be over-specified.

Customization Options

At Shaanxi CXMET Technology Co., Ltd., we support full customization of Gr12 Titanium Alloy Bars to meet your application and design needs:

-

Custom lengths and diameters

-

Machined ends or drilled holes

-

Special surface treatments or coatings

-

Ultrasonic or third-party testing upon request

-

OEM and ODM solutions available for global clients

We also provide mill test certificates, inspection reports, and material traceability to support quality assurance and compliance.

Primary Advantages of Gr12 Titanium Alloy Bar

-

Optimized for corrosion resistance: Specifically engineered for use in hot acids, saltwater, and chemical solutions

-

Efficient weight-to-strength ratio: Lighter than stainless steel yet offers comparable structural performance

-

Excellent thermal stability: Suitable for applications requiring operation across a wide range of temperatures

-

Longer lifespan: Reduced replacement and maintenance costs due to corrosion resistance and structural reliability

-

High fatigue resistance: Ideal for dynamic environments or where load cycling is present

-

Cost-effective: Lower lifecycle cost compared to other corrosion-resistant metals

Packaging and Logistics

We ensure all titanium bars are securely packaged for international transit:

-

Bundled with waterproof wrapping and wooden cases

-

Labeled with complete product details and traceability codes

-

Export-standard packaging in compliance with ISPM15 and international shipping rules

-

Fast delivery through air, sea, or express logistics depending on client urgency

-

Global shipping experience with professional customs handling

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Us – Shaanxi CXMET Technology Co., Ltd.

Shaanxi CXMET Technology Co., Ltd. has been a leader in non-ferrous metal manufacturing since 2005. With over 20 years of industrial expertise, we stand out due to:

-

Extensive Product Range: Titanium, nickel, tantalum, niobium, tungsten, molybdenum, and zirconium metals

-

Outstanding Production Capacity: 50000 square meters of production facilities with modern forging, machining, and testing equipment

-

Advanced Technological Development: Innovation-driven approach with more than 80 professional engineers

-

Customized Engineering Solutions: OEM and ODM services tailored to client-specific challenges

-

Strong Industry Reputation: Products trusted and approved by clients in aerospace, chemical, energy, medical, and marine sectors

-

Strategic Location: Situated in China’s Titanium Valley, with access to world-class titanium resources

Our corporate culture is based on integrity, continuous development, innovation, and service excellence. We prioritize quality and customer satisfaction in every project we undertake.

Frequently Asked Questions (FAQ)

Q1 What is the main difference between Gr12 and other titanium grades

Gr12 offers superior corrosion resistance with moderate strength due to the addition of molybdenum and nickel, making it suitable for aggressive chemical environments unlike CP titanium.

Q2 Can you supply small quantity orders for trial use

Yes. We support both small sample orders and full-scale production runs to meet customer evaluation needs.

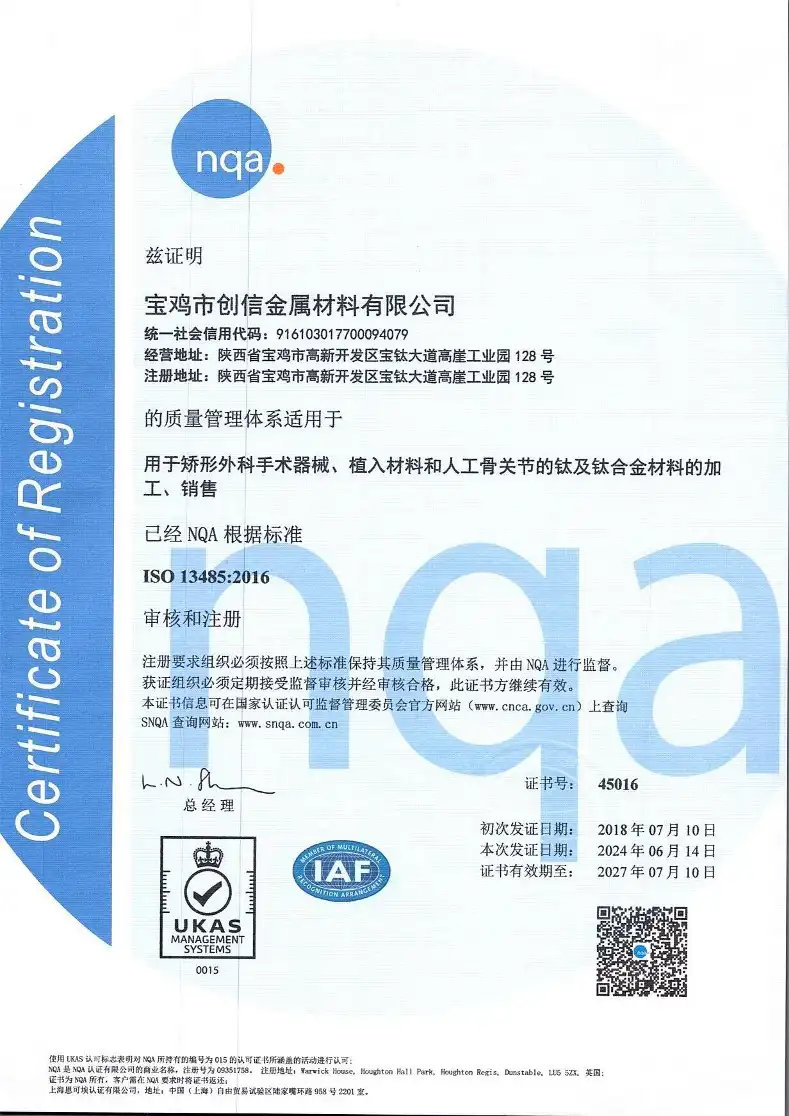

Q3 What certifications do you offer

We provide ISO 9001, mill test certificates, third-party inspection reports, and compliance documentation based on project requirements.

Q4 Can I customize the size or finish of the bar

Absolutely. We support custom sizes, machining, and surface finishes according to your design and performance needs.

Q5 How long is the lead time

Typically 7 to 15 working days depending on stock availability and customization level.

Contact Us for the Latest Price and Custom Solution

Shaanxi CXMET Technology Co., Ltd. welcomes global buyers to partner with us for reliable titanium alloy solutions. We offer competitive pricing, fast delivery, and professional support.

Email sales@cxmet.com

Tel & WhatsApp +8615891192169

Let our team help you find the right Gr12 Titanium Alloy Bar solution for your project today.

hotTags:High Standard Gr12 Titanium Alloy Bar,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

Titanium Hex Bar For Sale

Brand: CXMET

Place Of Origin: China

Material: Pure titanium titanium alloy

Grade: Gr1,Gr2,Gr5,Gr7,Gr12,etc

Color: Ti Natural

Applacation: Industry Diameter:60-50mm

Length <6000mm(nomal size)

Gr9 Titanium Bar

Brand: CXMET

Place Of Origin: China

Grade: Titanium GR-9

Standard: ASTM B348 / ASME SB348, AMS 4976, AMS 4956

Type: Seamless / Welded / Fabricated / LSAW Pipes

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

Titanium 6Al7Nb Medical Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Rod

Application: Industrial

Technique: Cold Rolled

Grade: GR1

Shape: Round

Density: 4.5g/cm3

6Al4V AMS 4928 Titanium Bar

Brand: CXMET

Place Of Origin: China

Diameter 2

Max Length 144

Grade: Grade 5

Full Length true

Material: Titanium

Shape: Bar-Round

Custom: Cut Warehouse 1

Alloy: 6AL-4V Grade 5

Titanium Square Bar

Brand: CXMET

Place Of Origin: China

Material: GR1,GR2,GR3,GR4,GR5,6AL4VEli,GR7,GR9,GR12,GR23

Standards: ASTM B348,ASTM F67,ASTM F136

Surface : Polished bright,machined ,grind

Supply condition: Hot rolling ,cold drawing ,annealed

Shape: Square

Dia 10mm Titanium Rod In Medical

Brand: CXMET

Place Of Origin: China

Shape: Round

Grade: Gr5

Weight: According the dimension

Processing Service :Rolling, Ground

Material: titanium

Surface :Treatment Ground

MOQ: 10 KG

Standard :ASTM B348 ASTM F136

Package: Standard Wooden Case

Stock Size: Dia3-40mm Titanium Rod

tianium Alloy 6Al-2Sn-4Zr-6Mo Round Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial, Medical

Technique: Hot Rolled

Shape: Round

Classification: Commercially Pure

High Quality Gr1 Pure Titanium Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Cold Rolled

Grade: GR1

Shape: Round

Transport Package: As Your Requirements