- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Ti-13Nb-13Zr Titanium Rod

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Cold Rolled

Grade: Gr1 Gr2

Shape: Round

Density: 4.5g/cm3

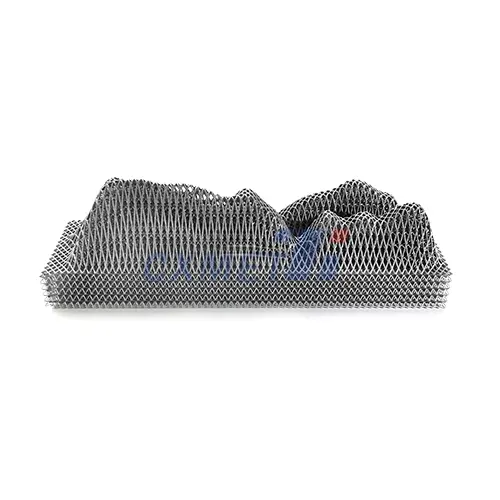

Ti-13Nb-13Zr Titanium Rod Product Introduction

Ti-13Nb-13Zr Titanium Rod is an advanced alpha-beta titanium alloy rod that combines excellent strength, outstanding corrosion resistance, and superior biocompatibility. This titanium alloy features a carefully balanced chemical composition primarily of titanium, niobium, and zirconium. Its unique microstructure delivers enhanced mechanical properties while maintaining exceptional toughness and ductility. Widely used in demanding industrial sectors, Ti-13Nb-13Zr is a preferred choice where performance and reliability are critical. Shaanxi CXMET Technology Co., Ltd., as a leading titanium manufacturer, offers high-quality Ti-13Nb-13Zr Titanium Rods that meet stringent international standards.

Features of Ti-13Nb-13Zr Titanium Rod

Ti-13Nb-13Zr Titanium Rod stands out due to its:

-

Excellent corrosion resistance especially in oxidizing and chloride-containing environments

-

High tensile strength combined with good elongation and fatigue resistance

-

Outstanding biocompatibility, making it suitable for medical implants and devices

-

Superior weldability and formability, enabling complex machining and fabrication

-

Good resistance to stress corrosion cracking, providing durability in harsh chemical environments

-

Lightweight yet strong, offering an ideal strength-to-weight ratio for aerospace and marine applications

Specifications of Ti-13Nb-13Zr Titanium Rod

Typical chemical composition (weight percent):

-

Titanium balance

-

Niobium 12 to 14

-

Zirconium 12 to 14

-

Trace amounts of oxygen, iron, carbon, nitrogen within industry standards

Mechanical properties:

-

Tensile strength 850 to 950 megapascals

-

Yield strength 780 to 850 megapascals

-

Elongation 10 to 15 percent

-

Hardness approximately 320 HV

Available sizes:

-

Diameter range from 6 millimeters to 200 millimeters

-

Lengths customizable according to client needs

-

Surface finish options including polished, annealed, and sandblasted

|

|

|

|

|

|

Applications of Ti-13Nb-13Zr Titanium Rod

Ti-13Nb-13Zr Titanium Rod is highly valued across multiple industries including:

-

Aerospace components where strength and corrosion resistance are vital

-

Marine engineering parts exposed to saltwater and harsh conditions

-

Chemical processing equipment requiring materials resistant to acids and chlorides

-

Medical devices and implants due to its biocompatibility and non-toxic nature

-

Energy sectors including heat exchangers and power plant components

-

Automotive industry for high-performance and lightweight structural parts

|

|

|

|

|

|

Working Environment of Ti-13Nb-13Zr Titanium Rod

This alloy excels in environments such as:

-

Highly corrosive chemical atmospheres with acids and oxidizers

-

Marine and offshore settings with prolonged exposure to seawater

-

High fatigue and cyclic load conditions

-

Biomedical environments inside the human body

-

Moderate to high temperature applications up to 600 degrees Celsius

-

Environments requiring strong resistance to stress corrosion and cracking

Customization of Ti-13Nb-13Zr Titanium Rod

At Shaanxi CXMET Technology Co., Ltd., we offer full customization for Ti-13Nb-13Zr Titanium Rods including:

-

Customized dimensions and tolerances to fit specific engineering designs

-

Tailored heat treatments to achieve desired mechanical properties

-

Surface treatments for enhanced corrosion resistance or appearance

-

Precision machining and cutting services to meet exact specifications

-

OEM solutions to support brand-specific requirements

Main Advantages of Ti-13Nb-13Zr Titanium Rod

-

Combines high strength with excellent ductility for versatile applications

-

Exceptional corrosion resistance reduces maintenance and extends service life

-

Superior biocompatibility allows safe use in medical and dental implants

-

Light weight contributes to fuel efficiency and weight reduction in aerospace and automotive

-

Stable mechanical properties under diverse environmental conditions

-

Enhanced weldability supports complex fabrications and assemblies

Packaging and Logistics

We package Ti-13Nb-13Zr Titanium Rods with utmost care to ensure safe delivery:

-

Each rod is individually wrapped with protective film or plastic to prevent surface damage

-

Wooden crates or reinforced cartons used for heavy or large quantity shipments

-

Strict quality checks and documentation accompany every shipment

-

Logistics partners chosen for reliable, timely global delivery by air or sea

-

Flexible shipping terms including FOB, CIF, and EXW

|

|

|

|

Company Overview

Shaanxi CXMET Technology Co., Ltd., founded in 2005, is headquartered in China's Titanium Valley and operates a 50,000 m² facility. With 10 million RMB in registered capital and over 80 technical staff, we specialize in R&D, manufacturing, and exporting of non-ferrous and refractory metals, including titanium, nickel, tantalum, niobium, zirconium, molybdenum, and tungsten.

Our materials serve industries ranging from marine and oil & gas to medical, chemical, electronics, and aerospace. We uphold integrity, development, innovation, and excellence in service. Our mission is to create value for clients, benefit our enterprise, and support employee growth. With a forward-looking vision, we strive to innovate and lead the global titanium market.

Factory show

|

|

|

|

Production workshop

|

|

|

|

|

|

Production Equipments

Main Products

Why Choose Shaanxi CXMET Technology Co., Ltd.

Founded in 2005 with a registered capital of 10 million RMB, Shaanxi CXMET Technology Co., Ltd. occupies 50,000 square meters in China’s famous Titanium Valley. We specialize in titanium, nickel, tantalum, niobium, tungsten, molybdenum, zirconium, and their alloys. Our company has more than 80 professional technicians committed to innovation and quality. We continuously develop new materials and processing techniques to meet international market demands.

Our products are trusted worldwide and widely used in marine, petroleum, chemical, power, metallurgy, medical, sports electronics, vacuum, and coating industries. Integrity, development, innovation, and excellence define our corporate culture. We operate transparently and maintain strict quality controls to build long-lasting customer trust.

We offer:

-

Extensive product range covering multiple alloy grades

-

Outstanding production and processing capabilities

-

Leading technology development and R&D strength

-

Customized solutions to fit diverse industry requirements

-

High quality products with competitive pricing

-

Professional customer service and technical support

FAQ

-

What is the typical lead time for Ti-13Nb-13Zr Titanium Rod orders?

Our standard lead time is 2 to 4 weeks depending on quantity and customization. -

Can you provide test reports and certifications?

Yes, we supply full material test reports, chemical analysis, mechanical tests, and certifications such as ISO and ASTM. -

Do you offer machining or cutting services?

Yes, precision machining, cutting, and surface treatments are available on request. -

Is small quantity order acceptable?

Yes, we support both small and large volume orders. -

What shipping methods do you provide?

We offer sea freight, air freight, and express courier services according to client preference.

Contact Us

We welcome global buyers to partner with Shaanxi CXMET Technology Co., Ltd. for premium Ti-13Nb-13Zr Titanium Rods. Reach out to us today for quotations, technical consultation, and customized services.

Email: sales@cxmet.com

Tel and WhatsApp: +86 15891192169

hotTags:Ti-13Nb-13Zr Titanium Rod,supplier,wholesale,China,factory,manufacturer,OEM,Customized,trader,for sale,in stock,free sample,for sale.

YOU MAY LIKE

Titanium 6Al7Nb Medical Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Rod

Application: Industrial

Technique: Cold Rolled

Grade: GR1

Shape: Round

Density: 4.5g/cm3

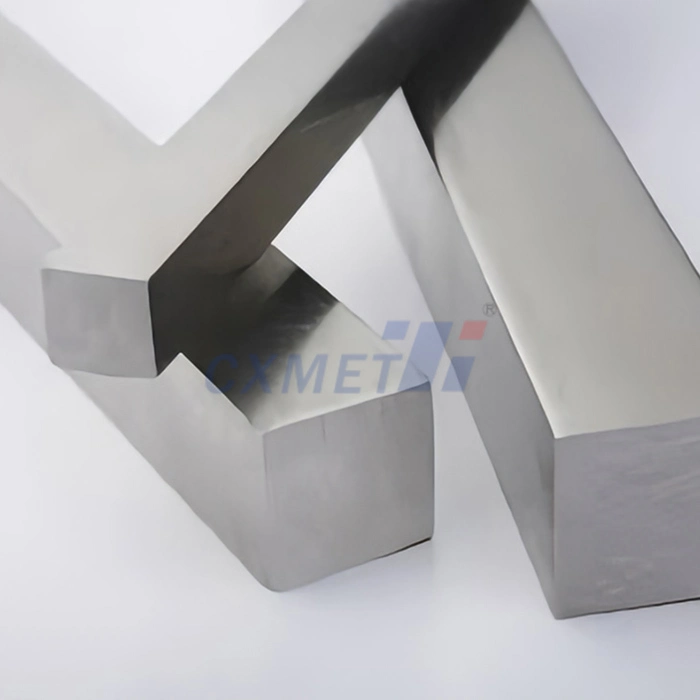

Gr12 Titanium Square Bar

Brand: CXMET

Place Of Origin: China Shape:Square

Grade: Gr12

Standard: ASTM B348

Technique: Rolling

Certificates: ISO 9001:2015

Titanium AMS 6242 Rod For Aerospace

Product name: 6al-4v titanium round

bar

Brand: CXMET

Place Of Origin: China

Application:Aerospace

Grade:Gr1

Standard: AMS4928

Density: 4.51g/cm3

Technique: Rolled

Shape: Round

Surface: Polished

Color: Sliver

Certificates: ISO 9001:2015

Gr7 Titanium Rod

Brand: CXMET

Place Of Origin: China

Standrd: ASTM B348 ASTM F136 AMS4928 ASTMF1295

Specifaction φ>6mm Length(Max)6000mm

Surface :Bright

Technology: Forging/Rolling

Content of Pb: 0.12---0.25%

Application: Medical, Aviation, Petrochemical, Metallurgy, Electroplating

Vacuum: Coating, Sports and other Industries.

Titanium Welding Rod

Brand: CXMET

Place Of Origin: China

Grade: Gr1 Gr2 Gr7 Gr5

Ti (Min): 99.6%

Strength: 345MPa

Surface: Pickling Polished

Shape: Spool Coil Straight

Standard: ASTM B863

Certification: ISO9001:2015

Strength: 435MPa

Application: Industrial

tianium Alloy 6Al-2Sn-4Zr-6Mo Round Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial, Medical

Technique: Hot Rolled

Shape: Round

Classification: Commercially Pure

titanium Grade 4 Round Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial, Medical

Technique: Cold Drawn/Hot Rolled/Forged

Grade: Gr4

Shape: Round/Square/Hexagonal/Wire

Diameter: 1-450 mm

High Quality Gr1 Pure Titanium Bar

Brand: CXMET

Place Of Origin: China

Type: Titanium Bars

Application: Industrial

Technique: Cold Rolled

Grade: GR1

Shape: Round

Transport Package: As Your Requirements